Received: April, 2015

DOI 10.17677/fn20714807.2015.04.03

Fluorine Notes, 2015, 101, 5-6

Impact of Fluorine Containing Schungite on the Properties of Polymer Composition Materials

N.A.Rahimova1, V.P. Medvedev 1, T.A. Kurilenko1, V.S. Avilova1, A.A. Okolelova1, A.I. Rahimov1,2

1Volgograd State Technical University, 400131, Russia, Volgograd, Lenin prospect, 28

e-mail:

organic@vstu.ru

2Institute of Chemical problems of Ecology ANS RF, 400066, Volgograd PO box 127,

e-mail:

rakhimov@sprint-v.com.ru

Abstract:Modification of schungite using octafluoropentanol and introducing of fluorine containing schungite into polymer composition materials allows controlling their physical and mechanical properties by alterting fluorine concentration in schungite and the amount of fluorine containing modifier in the composition

Keywords: Schungite, co-polymer of isoprene and butadiene, dibutyltin dilaurate, polymers

Introduction

One of the important tasks standing before chemical industry is creation of new materials of high exploitation characteristics (durability, stability, elasticity, wear resistance and others) and decreasing of negative man’s impact on environment due to rational use of raw materials and natural resources [1-4].

Using of schungite as modifying filler is a promising direction of modification of mechanical rubber materials. Schungite – is a natural organic silicate of a complex composition, where one of the components is a fullerene like schungite carbon. At that, its availability and low price compare to such traditional fillers as zinc dioxide, titanium dioxide is an attractive factor.

Using of micro- and nanomodifiers is a promising direction of modification. Poly- and perfluorinated compounds are of interest if indicated for those purposes, as due to the unique nature of fluorine atom they provide hydrolytic resistance, light-, thermal, and wear resistance and other useful characteristics to polymeric materials. However, introduction of poly- and perfluorinated modifiers into polymer matrix in small quantities is connected as a rule with complications of their even distribution by volume [5]. Due to that the modification of schungite using polyfluorinated compounds can be used for providing the compositions with a number of unusual physical and chemical technological properties necessary for production of general mechanical rubber goods.

Due to peculiarities of its chemical and physical structure schungite positively influences the properties of rubber, in particular, it can be used for full or partial replacement of sulphuric vulcanization activators. Taking into account the specific character of chemical composition and uniqueness of schungite structure – the presence of metals’ oxides, carbon in the form of graphite, fullerenes, nanocarbonic tubes as well as silicon oxide and silicates in it we can suppose, that it is highly active towards halogen containing elastomers, particularly the impact on the structuring processes of elastomers containing functional groups, which contain active atoms of halogens, including chlorine and fluorine compare to traditional mineral fillers (kaolin, talc etc.). On the basis of chemical composition, diffylic nature and specificity of schungite surface containing active centres it is becoming perspective to study the impact of schungite in a principally new way, due to what the powders of schungite rock are being mixed with all known compounds (aqueous suspensions and fluoroplastics, caoutchoucs, resins and cements etc.). The ability to create highly filled compositions, including the ones based on caoutchoucs is a result of high compatibility of schungites with cohesives.

Due to that, a necessity to study the impact of fluorine containing schungite on the properties of composition materials based on Polytan and oligodienutrients (for example, using of isoprene and butadiene co-polymer of PDI-1K mark) arose, that will allow enhancing the economical and productive showings of polyurethanes at account of using new perspective fillers.

Experimental Part

Composite containing fluorine containing fillers are of practical interest as their introduction into polymer improves the wear resistance of the material [6, 7]. At that, the coatings mainly preserve the properties typical for initial materials, including resistance to aggressive media.

Polyfluoroalkylation of schungite was carried out by treating its particles with polyfluorinated alcohol - 2.2.3.3.4.4.5.5- octafluoropentanol (OFP) and isopropyl alcohol. Later the obtained consistence was being dispersed in ultra-sound homogenizer vibracell Ultrasonic Processor at 200 kHerz for 10 min. After that, isopropyl alcohol was being isolated in the process of vacuum filtration. The residue is being filtrated using Buchner funnel through ash-free filter of 9-11 cm diameter evenly distributing the residue on the whole surface of filter to carry out the analysis. Then the filter is carefully taken from the funnel and dried up. The obtained samples contained 2.57% and 3.50% of fluorine.

Polytan 4000 based on polyoxipropyleneglycole and composition based on oligomeric caotuchouc – co-polymer of isoprene and butadiene of PDI-1K mark containing chlorinated paraffin HP-470 and chalk (as a filler) were taken as the initial components of used polyurethanes. Caoutchouc concentration in the composition is 25,6 %.

Isocyanate prepolymer BFM based on polyoxypropyleneglycole, polyisocianate (PIC), glycerine and Dibutyltin dilaurate (DBTDL, CAS 77-58-7) catalyst were used in the composition containing Polytan for hardening. Per 53 mass parts of Polytan 4000 we took BFM -24 mass parts, PIC – 10,8 mass parts., glycerine –0,5 mass parts, DBTDL – 0,5 mass parts.

Polyisocyanate, glycerine and catalyst – DBTDL were used for hardening as the components of the composition based on co-polymer of isoprene and butadiene of PDI-1K mark. The concentration of ingredients for 100 mass parts of caoutchouc composition was as follows: PIC – 5 mass parts, glycerine – 0,76 mass parts, DBTDL – 0,5 mass parts.

10-30 mass parts of modified schungite per 100 mass parts of the initial composition were introduced into the composition based on caoutchouc of mark PDI-1K. It was mixed for 5-10 min till formation of homogenous mass, then one by one other ingredients of the composition were added: 5 mass parts of PIC, 0,76 mass parts of glycerine, 0,02 mass parts of DBTDL and mixing was repeated for 5 minutes. The obtained mixture was poured into the forms and kept for 6 days at 18-25 °С. The concentration of fluorine in schungite amounted to 2,57 and 3,50 %.

The composition based on polypropyleneglycole was prepared as follows: 53 mass parts of Polytan mark P 4000 were put into the 200 cm3 vessel, The composition based on polypropyleneglycole was prepared in a following way: 53 mass parts of Polytan of P4000 mark were loaded into the vessel, from 10 to 30 mass parts of modified schungite were put there as well, it was mixed for 5-10 min till obtaining a homogeneous mass, then one by one other ingredients were added:

10.8 mass parts of PIC, 0,5 mass parts of glycerine, 24 mass parts of BFM, , DBTDL and then again it was mixed for 5 minutes.

Deformation and strength properties were determined according to Russian State Standard GOST 270-75 (analogue ISO 37, ASTM D412) [8], constancy of compositions was determined by GOST 263-75 (ISО 7619) [9].

Results and Discassion

The impact of modified schungite can be evaluated by the alteration of composition properties [8]. As a rule, the introduction of filler changes the morphology of polymer. That’s why it is reasonable to evaluate the impact of fluorine containing filer containing octafluoropenthyl fragment on the properties of composition material based on Polytan Р 4000 and co-polymer and butadiene of PDI-1K mark.

In the present work we have been determining the impact of the amount of fluorine containing filer on the properties of composition materials and studying physical and chemical properties of the obtained compositions (Pictures 1 – 5).

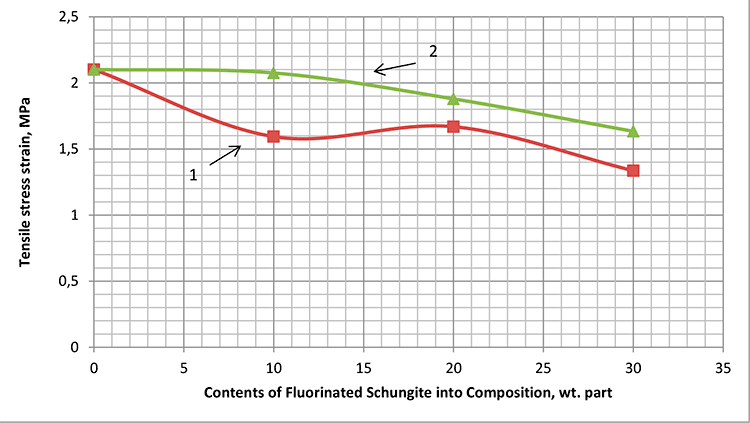

Pic. 1 The Dependency of Conditional Durability During The Process of Stretching On the Amount of Added Fluorine Containing Schungite In the Composition Based On Polytan. 1– Fluorine Content - 2,57% ; 2 – Fluorine Content - 3,50%

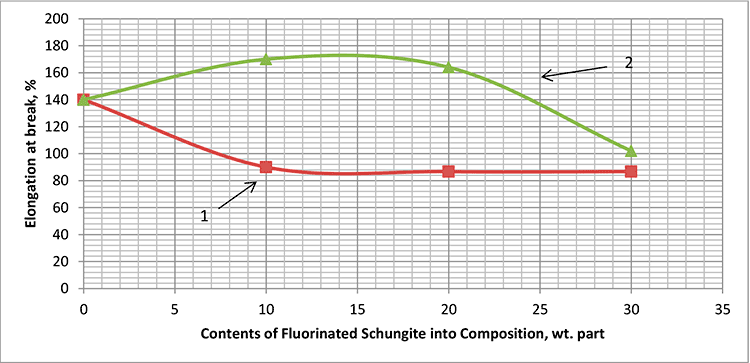

Pic.2 The Dependency of Tensile Strain At Breakage On The Amount Of Added Modified Schungite In The Composition Based On Polytan; 1 – Fluorine Content Is 2, 57%; 2- Fluorine Content Is 3,50%

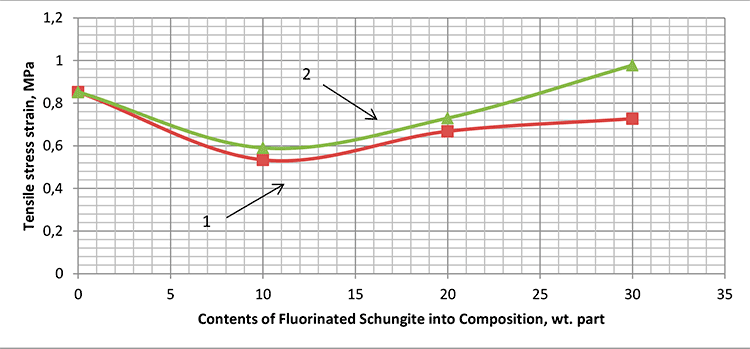

Pic. 3 The Dependency Of Conditional Durability At Stretching On The Amount of Added Fluorinated Schungite In The Composition Based On Co-polymer Of Isoprene and Butadiene of PDI-1K Mark. 1- Fluorine Content Is 2,57% ; 2 – Fluorine Content Is 3,50%

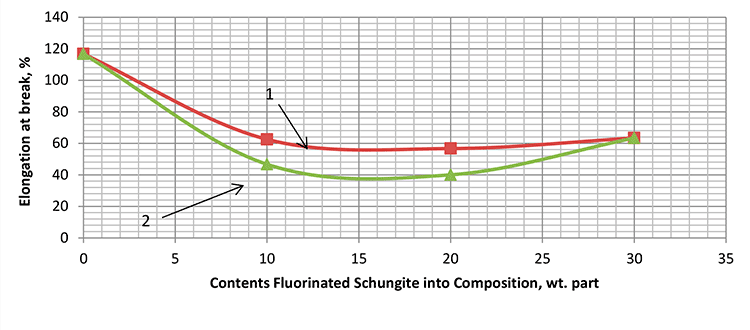

Pic. 4 The Dependency of Tension Strain At Breakage On The Amount Of Added Fluorinated Schungite In The composition Based On Co-Polymer Of Isoprene And Butadiene Of PDI-1K Mark. 1- Fluorine Content Is 2,57% ; 2 – Fluorine Content Is 3,50%

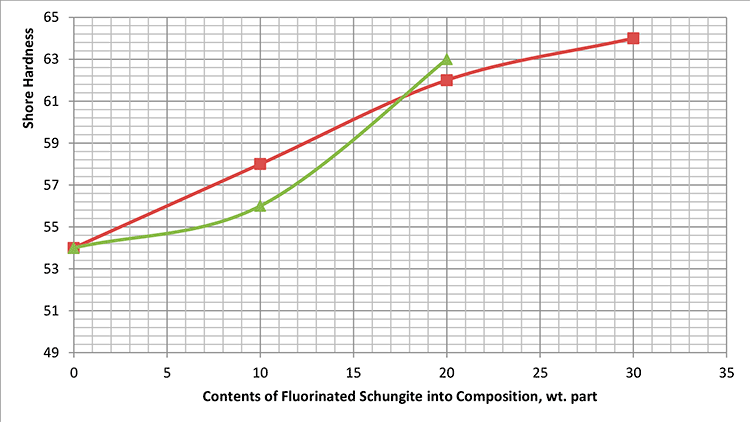

Pic. 5 The Dependency of Shore Hardness On The Amount Of Added Fluorinated Schungite Into The Composition Based on Co-Polymer Of Isoprene And Butadiene Of Mark PDI-1K. 1 Fluorine Content - 2,57% ; 2 - Fluorine Content 3,50%.

At Picture 1 you can see the influence of modified schungite of different content of fluorine on the hardness of material from the composition based on Polytan P 4000. Looking at Picture 1 one can see, that the concentration of fluorine leads to insignificant decreasing in durability. At that, tensile strain at breakage (Pic. 2) significantly grows within the range of doses of modified schungite 10-20 mass parts at presence of octafluoropentyl fragments corresponding to concentration of fluorine of 3,50 %. It should be noted, that Shore hardness of obtained samples of elastomer material changes slightly (within the range of 62 – 66 digits).

A significant increase of durability together with the increase of schungite amount up to 30 mass parts with fluorine concentration of 3,50% is observed when introducing schungite with octafluoropentyl fragments into the composition based on co-polymer of isoprene and butadiene of PDI-1K mark. When introducing schungite up to 30 mass parts with octafluoropentyl fragments with fluorine content equal to 3,50% (Pic. 3) into the composition based on co-polymer of isoprene and butadiene of PDI -1K mark we observe a significant increase of durability. At that, decrease of elastomer samples’ tensile strain (Pic. 4) and Shore hardness growth (Pic. 5) should be noted.

Conclusions

It has been stated, that the modification of schungite using octafluoropentanol and introducing of fluorine containing schungite into polymer composition materials allows controlling their physical and mechanical properties by alterting fluorine concentration in schungite and the amount of fluorine containing modifier in the composition.

References

- Timofeeva V. A. Strukturnye izmeneniya poverhnosti polimernyh materialov v usloviyah ob"emnoj i poverhnostnoj modifikacii po dannym atomno-silovoj mikroskopii: Dis. … kand. khim. nauk. M., 2005.

- Kerber M.L. Polimernye kompozicionnye materialy: struktura, svojstva, tekhnologiya/ M.L. Kerber, V.M. Vinogradov, G.S ,Golovkin i dr.: pod. Red. A.A. Berlina.-SPb.: Professiya,2008.-560 s.

- Trenie i iznos ftorsoderzhashchih nanokompozitovpolidienuretan – organomontmorillonit / I.A. Novakov, N.A. Rahimova, A.V. Nistratov, V.F. Zheltobryuhov, S.V. Kudashev, O.A. Barkovskaya // Izv. VolgGTU. Seriya «Khimiya i tekhnologiya elementoorganicheskih monomerov i polimernyh materialov». Vyp. 9 :mezhvuz. sb. nauch. st. / VolgGTU. - Volgograd, 2012. - № 5. - C. 178-182.

- Vliyanie gidroksosilikatov metallov na svojstva rezinovyh smesej i ih vulkanizatov /O.O.Tuzhikov, B.A.Buravov, N.V.Sychev, '.A.Vaniev, O.I.Tuzhikov // Izv. VolgGTU. Seriya «Khimiya i tekhnologiya elementoorganicheskih monomerov i polimernyh materialov». Vyp. 13 :mezhvuz. sb. nauch. st. / VolgGTU. - Volgograd, 2014. - № 22. - C.80-84

- Vityaz' P.A. Osnovy nanotekhnologij i nanomaterialov/ P.A. Vityaz', N.A. Svidunovich. – Minsk: Vysh. shk., 2010. – 302 s.

- A.A. Ohlopkova, Adrianova O.A., Popov S.N. Modifikaciya polimerov ul'tradispersnymi polimerami.- Yakutsk: F. Izd–va SORAN, 2003.– 224 s.

- .Rahimova, N. A. Gidrofobizaciya bentonita poliftorirovannymi spirtami / N. A. Rahimova, S. V. Kudashev // Izvestiya VolgGTU: mezhvuz. sb. nauch. st. / VolgGTU. – Volgograd, 2010. – S. 49-53. – (Ser. Khimiya i tekhnologiya elementoorganicheskih monomerov i polimernyh materialov. Vyp. 7).

- GOST 270-75 Rezina. Metod opredeleniya uprugoprochnostnyh svojstv pri rastyazhenii.

- GOST 263-75 Rezina. Metod opredeleniya tverdosti po Shor A.

- Pol. D.R. Polimernye sistemy D.R. Pol, K.B. Bankel.-SPb.:nauchnye osnovy i tekhnologii: 2009.-606 s.

Recommended for publication by Prof. A. Rahimov

Fluorine Notes, 2015, 101, 5-6