Received: February, 2015

DOI 10.17677/fn20714807.2015.02.04

Fluorine Notes, 2015, 99, 5-6

THE STUDY OF IMPACT OF OCTAFLUOROPENTYL GROUP ON RHEOLOGICAL PROPERTIES OF CARBOXYMETHYL CELLULOSE GELS ON ITS SURFACE

N.A.Rahimova1, E.V. Petrosyan1, A.I. Rahimov1,2

1 Volgograd State Technical University, 400131, Russia, Volgograd, Lenin prospect,

28

e-mail: organic@vstu.ru

2Institute of Chemical problems of Ecology ANS RF, 400066, Volgograd PO box 127

Abstract: For the first time rheological particularities of aqueous solutions of carboxymethyl cellulose (CMC) polyfluoroalkylated under heterophase conditions have been revealed and it has been stated, that aqueous solution of sodium salt of carboxymethyl cellulose modified by octafluoropentyl fragment was a pseudo-plastic liquid.

Keywords: octafluoropentyl fragment, carboxymethyl cellulose, viscosity, elastic modulus.

Introduction

The development and implementation of new high-molecular compounds of improved applied properties are the essential tasks of contemporary chemistry.

The present task is solved by directed heterophase modification of polymer’s surface by octafluoropentyl fragment [1-7], which is introduced along hydroxylic groups of polymer matrix. This allows directed alteration of physical and chemical properties of polymers, and compositions, in which the present polymer can be used as one of the components.

Sodium salt of carboxymethyl cellulose (CMC) is one of the promising polymers for paint and varnish industry and drilling technics [8]. Primary hydroxyl groups are the reaction centre, by which the reactions with polyfluoroalkylchlorosulphite are going under heterophase conditions.

The presence of polyfluoroalkyl fragment in macromolecule of carboxymethyl cellulose changes physical and chemical properties of polymer’s gels. Due to this, we have conducted a detailed study of rheological properties of aqueous solutions (gels) of carboxymethyl cellulose. Studying of rheological properties of gels of polysaccharide of small concentration is informative as rheological properties are highly sensitive to alteration of molecular structure of polymer matrix. Rheological properties of aqueous solutions of polymers are directly connected with their application.

Studying of octafluoropentyl fragment impact on rheological properties of carboxymethyl cellulose gels in its molecule is the aim of the present work.

Experimental

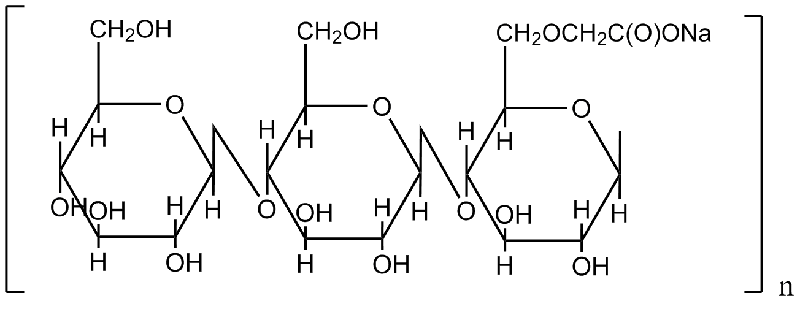

Carboxymethyl cellulose sodium salt of medium viscosity mark 85/1100 and the product of its polyfluoroalkylating are the subjects of our study. Structural formulas of the initial (1) and modified (2) polymers are listed below:

(1)

(2)

The rheological properties of aqueous solution of polymer (gel) have been studied for compositions of carboxymethyl cellulose of medium viscosity and its polyfluoroalkylated analogue using dynamic mechanical analysis (DMA) method at Micro Fourier Rheometer MFR 2100 (Australia) at preset temperature of 25 °С.

Results and Discussion

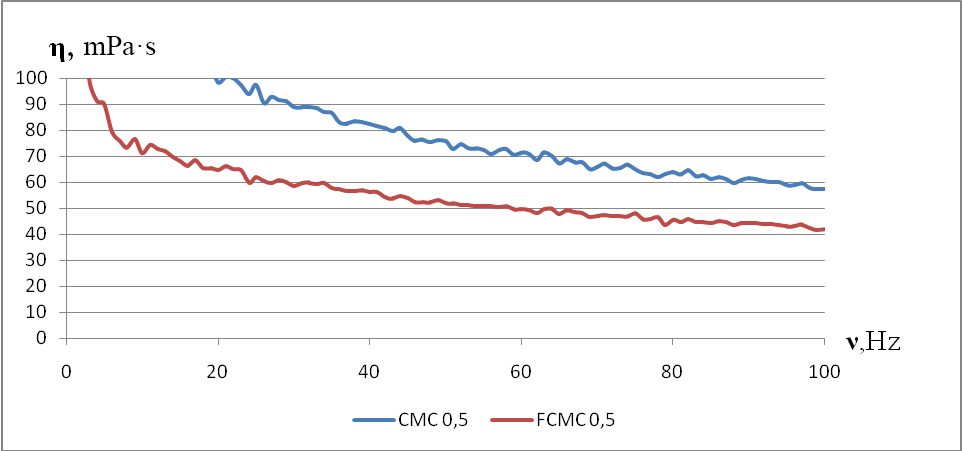

Due to the presence of quite stable spatial frame within the structure of polymer gels the studying of impact of octafluoropentyl group introduction in macromolecule on rheological properties of obtained compositions is possible. Viscous properties reflect the impact of polymer matrix structuring degree in aqueous solutions. The viscosity dependencies on the value of wave impact of frequency up to 100 Hz for 0,5% aqueous solutions of carboxymethyl cellulose and polyfluoroalkylated cellulose are presented at Picture 1. It can be seen, that the introduction of octafluoropentyl groups greatly decreases (down to 30%) the viscosity of obtained solution.

Picture 1. Alteration of Viscosity During The Process Of Wave Impact On 0,5% Aqueous Solution Of Carboxymethyl cellulose (1) And Octafluoropentyl Derivative Of Carboxymethyl cellulose (2).

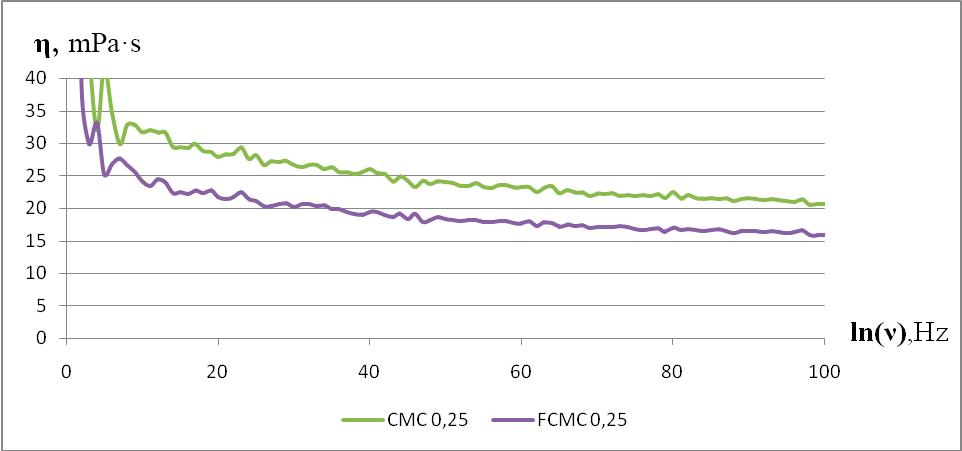

For gels of 0,25% concentration, which are presented at Picture 2 the viscosity ratio for modified and unmodified carboxymethyl cellulose solutions remains at level of 25% during wave function of the same frequencies influencing.

Picture 2. Alteration of Viscosity In The Process of Wave Impact On 0,25% Aqueous Solution of Carboxymethyl cellulose (1) And Octafluoropentyl Derivative Of Carboxymethyl cellulose (2).

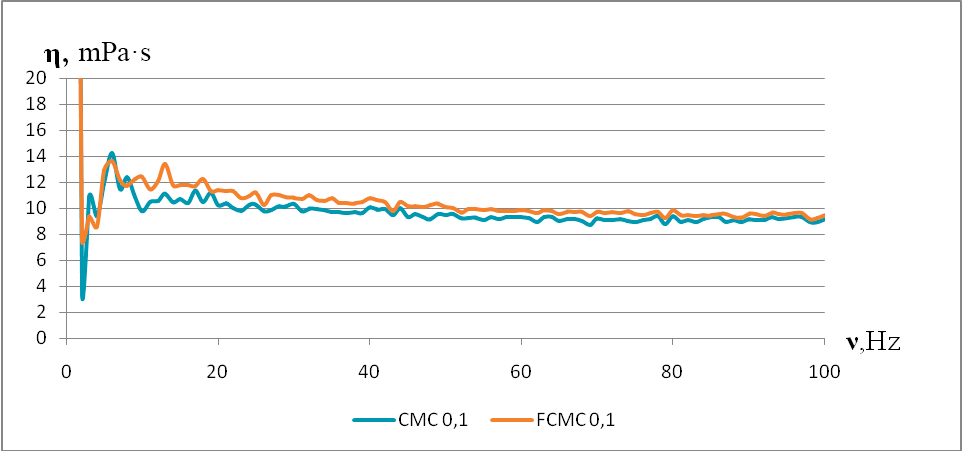

Viscosity properties of 0,1% solutions of carboxymethyl cellulose and polyfluoroalkylated carboxymethyl cellulose presented at Picture 3 are approximately at the same level and that most likely is due to the sensitivity of Micro-Furrier rheometer under conditions of low concentration of polymer in gel.

The present effect can be used in application, as giving specific properties to the polyfluoroalkyl fragments when aiming keeping viscosity under the conditions of low concentrations is vital information on the properties of modified polymer.

Picture 3. The Alteration of Viscosity In the Process Of Wave Impact On 0,1% Aqeous Solution Of Carboxymethyl cellulose (1) And Octafluoropentyl Derivative Of Carboxymethyl cellulose (2).

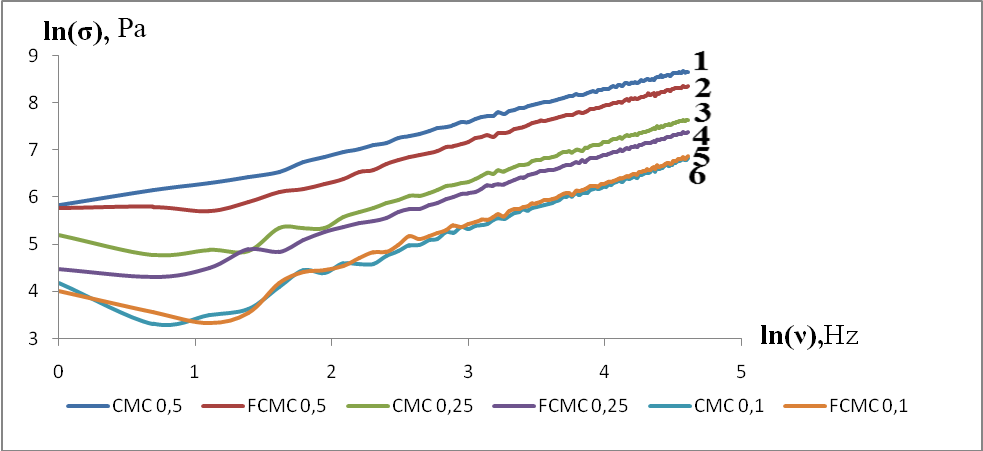

It is known, that the effective viscosity is a function of shift rate, which is replaced by the frequency of wave impact, and tension of shift. We shall use equation 1[9] to determine the tension of shift. Later we determine the flow index (it is below 1 everywhere) for curves of different concentrations by modeling the dependency of logarithm of shift tension on frequency logarithm. This points out the gels properties as non-newton pseudo-plastic liquids (Listed at Picture 4).

σ=η•ν (1)

Picture 4. Changing Of Logarithm Of Shift Tension From Logarithm Of Wave Impact Of Viscosity At Wave Impact On 0,5% Aqueous Solution Of Carboxymethyl cellulose (1), On 0,5% Aqueous Solution Of Octafluoropentyl Derivative Of Carboxymethyl cellulose(2), On 0,25% Aqueous Solution Of Carboxymethyl cellulose (3), On 0,25% Aqueous Solution Of Octafluoropentyl Derivative Of Carboxymethyl cellulose (4), On 0,1% Aqueous Solution Of Carboxymethyl cellulose (5) and On 0,1% Aqueous Solution Of Octafluoropentyl Derivative Of Carboxymethyl cellulose (6).

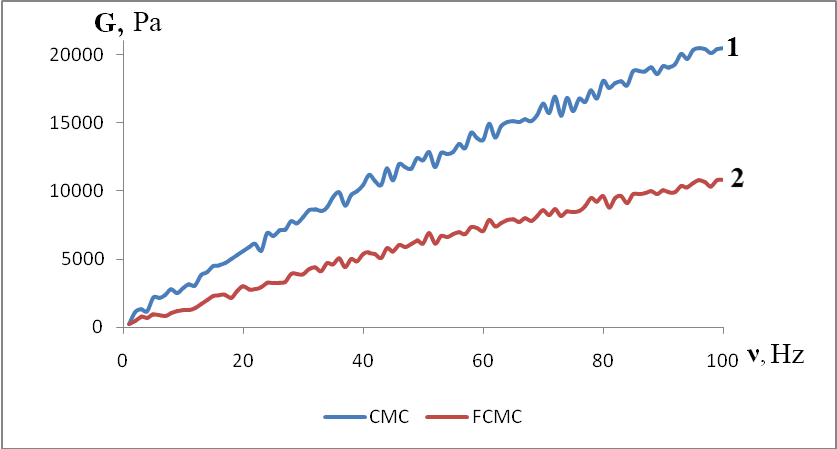

Elastic modulus of gel G is a rheological characteristic, which is connected to the density of coordination frame, which reflects degree of system structuredness. Data of G dependency on frequency for 0,5% solution can be found at Picture 5. Those gels can be referred to as high module, because the elastic modulus exceeds 500 Pa. Elastic modulus of unmodified carboxymethyl cellulose is almost twice as big as the elastic modulus of polyfluoroalkylated carboxymethyl cellulose. That is due to the fact that less number of stiches is formed when the polymer is modified, it is because of the polufluoroalkyl fragment’s presence, that fragment regulates lipophilic and hydrophilic balance towards the increasing of polymer’s hydrophobic properties.

Picture 5. Alteration Of Elastic Modulus During the Process Of Wave Impact On 0,5% Aqueous Solution Of Carboxymethyl cellulose (1) And Octafluoropentyl Derivative Of Carboxymethyl cellulose (2).

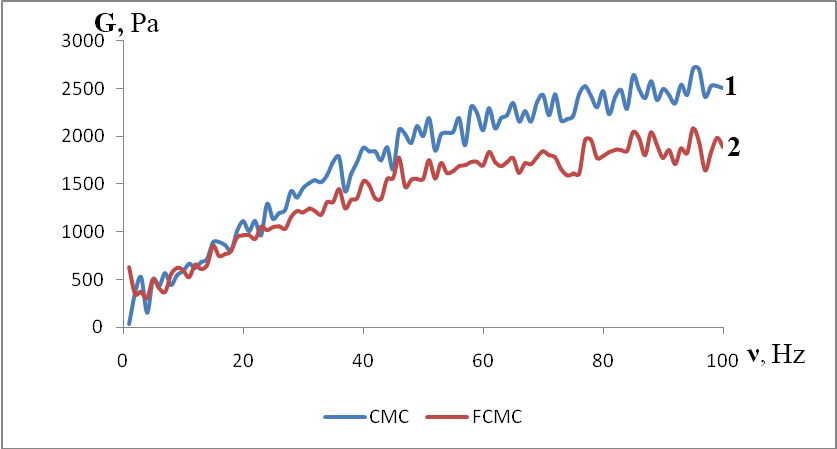

Data on elastic modulus dependency on wave fluctuations frequencies for 0, 25% solution are listed at Picture 6. Gels under consideration are also referred to as high module, because elastic modulus exceeds 500 Pa. However, elastic modulus of gel of unmodified carboxymethyl cellulose exceeds the elastic modulus of gel of polyfluoroalkyllated carboxymethyl cellulose for almost 30%. That obviously is due to the fact, that smaller concentration of polymer results in decreasing of influence of polyfluoroalkyl fragment on wetting ability decreasing.

Picture 6. Alteration of Elastic Modulus During The Process Of Wave Impact On 0,25% Aqueous Solution Of Carboxymethyl cellulose (1) And Octafluoropentyl Derivative Of Carboxymethyl cellulose(2).

The dependency of elastic modulus on fluctuation frequency for 0,1% solution has not been determined as it beyond the limits of apparatus sensitivity and doesn’t allow to determine the elastic properties of low viscosity gels.

The results of the experiment point out the fact, that dynamics of stitching of 3D frame is characterized by not only presence of sodium carboxylate groups (remains practically untamed) but also by the influence of polyfluoroalkyl fragment, which slows the processes of forming of 3D structure, that can have a positive effect on viability of formed gel. As it is known [10], that greater degree of polymer’s swelling corresponds to smaller density of stitching, that can lead to exclusion of possible syneresis and thus, regressing of physical and mechanical properties of gel, as the increasing of stitching density of 3D frame results in redudndancy of a greater part of solvent.

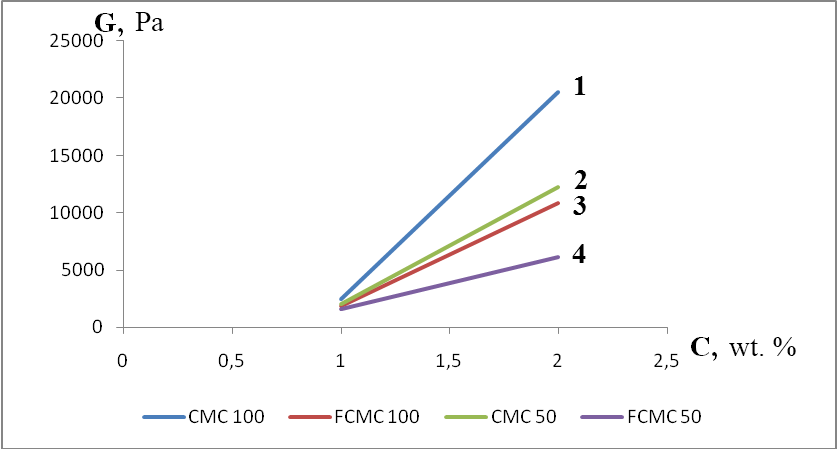

At Picture 7 you see the dependency of elastic modulus on concentration of carboxymethyl cellulose and polyfluoroalkylated carboxymethyl cellulose during the impact of wave function of different frequency on gels. It can be seen, that elastic modulus grows at increasing of polymer’s concentration in gel’s composition, as well as it is growing due to increase of impact of wave function, that indicates polymer’s stitching processes during more intensive impact on it. Elastic modulus must be as higher as faster the stitching process passes. It should be noted, that elastic properties of gel of carboxymethyl cellulose during 50 Hz frequency wave impact on it behave themselves practically proportional to the gel of polyfluoroalkylated carboxymethyl cellulose during 100 Hz wave impact on it. That indicates shifting of polymer’s functions from elastic towards viscous properties after modification using polyfluoroalkyl fragment.

Picture 7. Alteration Of Elastic Modulus Depending On Gel’s Concentration During Impact of Different Frequency On Gel: 100 Hz on Carboxymethyl cellulose (1), 50 Hz On Carboxymethyl cellulose (2), 100 Hz On Octafluoropentyl Derivative Of Carboxymethyl cellulose (3) and 50 Hz On Octafluoropentyl Derivative Of Carboxymethyl cellulose (4).

Conclusions

Based on the data of rheological studies applying Micro Fourier method it has been stated, that both gel based on sodium salt of carboxymethyl cellulose with octafluoropentyl group and unmodified polymer possesses the properties of pseudo-plastic liquids. The impact of polyfluoroalkyl fragment on viscous and elastic properties of aqueous solution of carboxymethyl cellulose has been studied and we have found the effect leading to increase of elastic properties of polymer under the influence of frequency within the range of up to 100 Hz under the conditions of low concentrations (0,1-0,5%) of gel in the solution.

References

- A.I. Rahimov, O.V. Vostrikova, E.V. Petrosyan, The distinctive features of carboxymethylcellulose sodium salt surface polyfluoroalkyl-modification, Fluorine notes, Vol. 4(89), 2013, URL: /public/2013/4_2013/letters/index.html

- A.I.Rakhimov, A.V.Nalesnaya and O.V.Vostrikova, A New Method for Preparing Polyfluorinated Ethers, Russian Journal of General Chemistry, Vol. 74, No. 4, 2004, p. 633.

- A. I. Rakhimov and R. V. Fisechko, Reaction of Polyfluoroalkyl Chlorosulfites with Benzyl Alcohols, Russian Journal of General Chemistry, Vol. 77, No. 10, 2007, p. 1813, DOI:10.1134/S1070363207100258

- A. I. Rakhimov and R. V. Fisechko, New Synthesis of Polyfluoroalkyl Cyclohexyl Ethers, Russian Journal of General Chemistry, Vol. 78, No. 2, 2008, p. 323, DOI: 10.1134/S1070363208020266

- A. I. Rakhimov, A. V. Nalesnaya and R. V. Fisechko, Features of Catalysis in the Reaction of Polyfluoroalkyl Chlorosulfites with Saturated Monohydric Alcohols, Russian Journal of General Chemistry, Vol. 78, No. 11, 2008, DOI: 10.1134/S1070363208110169

- Patent of Russian Federation No. 2346926.

- A. I. Rakhimov, Synthesis of Polyfluoroalkyl Chlorosulfites and New Polyfluoroalkylation Reactions with Their Participation, Russian Journal of General Chemistry, Vol. 80, No. 8, 2010, p. 1626, DOI: 10.1134/S107036321008013X

- Patent of Russian Federation No. 2128188

- G. Vinogradov and A. Ya. Malkin, Rheology of polymers, Khimiya, Moscow, U.S.S.R., 1977, 438 pp (in Russian).

- Zubakova L. B., Tevlina A. S. and Davankov A. B. Synthetic Ion-Exchange Materials, Khimiya, Moscow, U.S.S.R., 1978, 184pp (in Russian).

Recommended for publication by Prof. A. I. Rahimov

Fluorine Notes, 2015, 99, 5-6