Received: October, 2012

Fluorine Notes, 2014, 96, 1-2

Chemistry and Technology of Polyfluorinated Organic Compounds Based on New Aggression Resistant Catalysts

Vladimir Y. Zakharov

State Educational Institution of Higher Professional Education

"Vyatka State University", 610000,

Kirov, Moskovskaya str. 36, Russia

e-mail: zakhar.05@mail.ru

Abstract: Scientific principles of selection of effective catalysts of direct gas-phase fluorination of organic compounds have been developed. The use of created catalysts improve existing and allow to develop the new technologies of polyfluorinated organic products.

Keywords: Organofluorine compounds, fluorine, cobolt trifluoride, isomerization, heterogeneous catalyst, catalytic fluorination.

(Continuation)

2.4. Catalytic Gas-Phase Fluorination of Hydrogen Containing Polyfluorinated Compounds

The replacement of hydrogen at carbon atom for fluorine at direct fluorination is characterized as it has been already noted, by isolation of significant amount of heat and is accompanied as a rule by high input of subsrate destruction. In the present part of the work the results regarding study of direct fluorination of polyfluorinated hydrogen containing compounds are listed. We also studied the opportunity of aimed qualitative increase of its selectivity when using heterogeneous contacts created based on developed principals of selection of direct fluorination effective catalysts.

2.4.1. Fluorination of 2,5,5,9-tetrahydro-2-perfluoromethyl-4-oxaperfluorononane

We have used 2,5,5,9-tetrahydro-2-perfluoromethyl-4-oxaperfluorononane (THN) as a model subsrate to study the impact of catalyst’s nature on selectivity and hydrogen replacement rate within the range of composition of polyfluorinated compounds. This substrate contains hydrogen at primary, secondary and tertiary carbon atoms; during its fluorination the following compounds may be formed:

|

Formula |

Substance |

Symbolic Representation |

|

CF3CF(CF3)CF2OCH2(CF2)4H |

5,5,9-trihydro-2-perfluoromethyl-4-oxaperfluorononane |

|

|

CF3CH(CF3)CF2OCFH(CF2)4H |

2,5,9-trihydro-2-perfluoromethyl-4-oxaperfluorononane |

|

|

CF3CF(CF3)CF2OCFH(CF2)4H |

5,9-dihydro-2-perfluoromethyl-4-oxaperfluorononane |

|

|

CF3CF(CF3)CF2O(CF2)5H |

9-monyhydro-2-prefluoromethyl-4-oxaperfluorononane |

|

|

CF3CF(CF3)CF2O(CF2)5F |

2-perfluoromethyl-4-oxaperfluorononane |

|

|

CF3CH(CF3)CF2OCH2(CF2)4H (substrate) |

2,5,5,9-tetrahydro-2-perfluoromethyl-4-oxaperfluorononane |

|

Quantitive analysis of the composition of forming products in this case allows estimating relative reactivity of hydrogen depending on the nature of fluorocarbonic fragment connected with it.

We shall note, that studying of THN fluorination is of practical interest – this process is one of the stages we developed together with Timoshenko Military Academy of Chemical Defense (Russia) /185,186/ utilization technology of perfluoroisobutylene (in the TFE pyrolysis products composition) obtaining perspective dielectric liquid of 2-perfluoromethyl-4-oxaperfluorononane (PFN).

Data on gas-phase catalytic fluorination of THN using elemental fluorine are listed in Tables 19 and 20; there are also results on homogenous gas-phase fluorination (in empty reactor).

From the listed data one can see, that fluorination in an empty reactor with no catalyst goes in a non-selective way forming mainly tetrafluoromethane, carbonyldifluoride (fixed in the form of CO2) and carbon-black (experiment 1, Table 20) – at that the grade of raw materials’ destruction exceeds 99% (experiment 1, Table 19).

Fluorination in the layer of known catalysts – metal copper (unmodified and silver coated) and nickel, also goes in a non-selective way – the raw materials’ destruction grade is at level of 85-95% (experiments 2-6, Table 19).

At that the composition of products of destruction is somewhat different, than during fluorination in an empty reactor – the main product of destructive fluorination is n-perfluorobutane (experiments 2-6, Table 20). The content of PFN in liquid products of fluorination is not high and occupies the 1-5 mass.% level.

Fluorination in the layer of melted calcium fluoride and aluminum alpha-oxide is characterized by some increase of selectivity – at that, the grade of destruction of raw materials falls to 50-80%, and the content of PFN in liquid products reaches 30 mass.% (experiments 7-10, Table 19). This result can be explained by the increase of specific surface of contact (compare to metal catalysts), that slows the destructive fluorination due to breakage of chains of this branched radical process.

We have mentioned above, that rate and selectivity of direct fluorination can be significantly increased during modification of α-Al2O3using nickel fluoride.The use of this catalyst while fluorinating of THN is accompanied by sharp increase of depth and selectivity of fluorination as experiments proved (experiments 11, 12, Table 19). Thus, the content of PFN in the liquid products of fluorination (523 K) when using NiF2/α-Al2O3and unmodified α-Al2O3 is 70,3 and 31,0 mass. %, and the grade of destruction of raw materials is 53 and 62% respectively.These results clearly illustrate, how big the role of nature of heterogenous contact is during fluorination and demonstrate the opportunity of practical application of NiF2/α-Al2O3 catalyst for obtaining of PFN and THN using method of direct fluorination.

Table 20. Composition of Gasiform Products of Destructive Direct Catalytic Fluorination of THN

|

# Acc. To Table 19 |

Composition Of Gasiform Products of Fluorination, volume % |

|||||||

|

CF4 |

C2F6 |

CO2 |

C3F8 |

n-C4F10 |

i- C4F10 |

i- C4F9H |

Others |

|

|

1 |

87,2 |

3,1 |

5,6 |

1,7 |

0,7 |

0,4 |

>0,1 |

1,3 |

|

2 |

10,5 |

8,5 |

20,3 |

11,0 |

42,4 |

1,7 |

5,2 |

0,4 |

|

3 |

8,3 |

7,5 |

16,7 |

5,3 |

49,3 |

1,2 |

7,0 |

4,7 |

|

4 |

2,8 |

1,8 |

15,1 |

7,1 |

59,1 |

1,8 |

6,8 |

5,5 |

|

5 |

11,3 |

7,7 |

11,5 |

12,8 |

46,7 |

2,4 |

5,1 |

2,5 |

|

6 |

20,1 |

7,9 |

12,7 |

12,0 |

38,0 |

2,0 |

4,4 |

2,9 |

|

7 |

24,6 |

15,9 |

15,2 |

5,4 |

25,0 |

2,5 |

10,5 |

0,9 |

|

8 |

15,8 |

10,5 |

11,4 |

4,4 |

40,4 |

2,9 |

14,0 |

0,6 |

|

9 |

8,0 |

13,8 |

13,8 |

10,5 |

28,2 |

11,0 |

11,8 |

2,9 |

|

10 |

0,6 |

10,0 |

6,8 |

8,4 |

55,7 |

9,4 |

7,1 |

2,0 |

|

11 |

0,6 |

0,6 |

18,8 |

10,9 |

52,2 |

9,1 |

5,0 |

2,8 |

|

12 |

0,4 |

1,0 |

22,8 |

17,5 |

42,0 |

10,6 |

0,8 |

4,9 |

Studying of selective fluorination products has shown, that activity of hydrogen atoms in THN molecule was different. Thus, 5,9-dihydro-2-perfluoromethyl-4-oxaperfluorononane is the only product of substitution of two hydrogen atoms in THN molecule, what indicates, that the activity of hydrogen at carbon tertiary atom and of unsaturated methylene group is significantly higher, than the one at primary carbon atom. The amount of 9-monohydro-2-perfluoromethyl-4-oxaperfluorononane in the reaction products is significantly higher, than the amount of 5-monohydro-2-perfluoromethyl-4-oxaperfluorononane, that indicates higher activity of hydrogen atom at partially substituted methylene group (at secondary carbon atom) compare to hydrogen atom at primary carbon atom.

Later, we have studied an opportunity of increasing the depth and selectivity of THN fluorination at NiF2/α-Al2O3 catalyst using two-section reactor with independent heatings. At that, we intended to carry out “soft” fluorination with minimum raw materials destruction at relatively low temperature in the first section of reactor, and to fluorinate polyfluorinated ethers forming at that up to PFN at increased temperature in the second section. Data is listed in Table 21.

Table 21. Direct Gas-Phase Fluorination of THN at NiF2/α-Al2O3 catalyst in a Two-Section Reactor (volume rate of input 50 hour-1, mole rate THN:fluorine:nitrogen =1:5:3) .

|

# |

Section Temperature, K |

Fluorine Conversion Grade, % |

Raw Materials Destruction Grade, % |

Composition of Liquid Products of Fluorination, mass.% |

|||||

|

1st |

2nd |

|

|

|

C5F12-xHx x=1ч3 |

Others |

|||

|

1 |

443 |

443 |

82 |

28 |

58,0 |

40,3 |

0,4 |

0,5 |

0,8 |

|

2 |

443 |

493 |

87 |

35 |

79,1 |

18,6 |

1,1 |

0,5 |

0,7 |

|

3 |

453 |

493 |

89 |

44 |

89,6 |

8,7 |

0,7 |

0,6 |

0,4 |

|

4 |

453 |

523 |

90 |

46 |

91,6 |

6,8 |

0,7 |

0,6 |

0,3 |

|

5 |

453 |

623 |

90 |

48 |

91,8 |

6,0 |

1,0 |

0,5 |

0,7 |

|

6 |

473 |

623 |

92 |

52 |

94,1 |

3,4 |

1,2 |

0,5 |

0,8 |

|

7 |

493 |

623 |

94 |

53 |

94,4 |

2,8 |

1,0 |

0,9 |

0,8 |

One can see from the listed data, that using the reactor with two-section heating allows increasing of PFN content in liquid products up to 94% mass. % without increasing the raw materials destruction grade ( ~ 50%) – the temperature values of first and second zones are 470-490 and 620K respectively.

We have also studied the opportunity of exhausting catalytic fluorination of polyfluorinated ethers containing in isolated by rectification PFN, in big excess of fluorine for the purpose of obtaining pure target product free from partially fluorinated addmixtures. Data is listed in Table 22.

Table 22. Purification of PFN from partially fluorinated compounds by direct gas-phase fluorination at NiF2/α-Al2O3 catalyst(volume rate of input 30 hour-1,mole rate PFN:fluorine:nitrogen = 3:1,5:1)1.

|

# |

Temperature K |

PFN Destruction Grade, % |

Concentration of partially fluorinated Addmixtures, mg/kg2 |

Composition of Organic products, mass. % |

|

|

|

|

||||

|

Initial Product |

1540 |

98,8 |

1,1 |

||

|

1 |

473 |

0,2 |

18 |

> 99,9 |

<0,1 |

|

2 |

523 |

0,3 |

11 |

> 99,9 |

<0,1 |

|

3 |

593 |

0,4 |

7 |

> 99,9 |

<0,1 |

|

4 |

623 |

0,4 |

4 |

> 99,9 |

<0,1 |

|

5 |

673 |

0,6 |

2 |

> 99,9 |

<0,1 |

1Fluorine conversion grade amounted to 7-15 %.

2In Recalculation per detached ion-fluorine.

Judging by the data listed above we can draw a conclusion, that fluorination of polyfluorinated ethers containing in PFN at NiF2/α-Al2O3 catalyst in the large excess of fluorine at 470-670 K allows achieving thin purification of target product from partially fluorinated addmixtures; at that the polyfluorinated ethers are fluorinated forming PFN.

Purification from partially fluorinated compounds grade (their concentration was controlled by the content of detached ion-fluorine) is increasing with fluorination temperature rise and at 670 K it reaches 99,9 %; the residual content of detached ion-fluorine in PFN at that amounts to 2-4 mg/kg (experiment 4, 5, Table 22). Here we should note, that content of detached ion-fluorine in perfluorodecaline used as a basic component of blood substituent is at the level of 6 mg/kg. The low grade of raw materials destruction, which even at 670K doesn’t exceed 1% draws attention. It is significant, that dielectiric durability of PFN purified that way is rather high and it exceeds 80 kB (the limit of measurement at AIM-90 detector).

Thus, the conducted study indicates the opportunity of directed qualitative increase of selectivity and rate of catalytic fluorination for the hydrogen polyfluorinated compounds as well.We should note, that data obtained have been checked on a pilot (experimental-industrial) scale and formed a base for developed PFN technology including direct fluorination of THN and purification of target product from hydrogen containing addmixtures by direct fluorination at NiF2/α-Al2O3.

2.4.2. Fluorination of α-hydro-ω-chlorineperfluoroalkanes

H(CF2)2Cl Fluorination.

1,1,2,2-Tetrafluorochloroethane (R-124) and octafluorocyclobutane (within the composition of their azeotrope mixture) are unutilizable multitonnage TFE production waste. Pentafluorochloroethane, which can be easily separated from octafluorocyclobutane by rectification can be obtained fluorinating 1,1,2,2-tetrafluorochloroethane; thus, the selective fluorination would allow setting the obtaining (from unutilizable fluoroorganic waste) of pentafluorochloroethane and octafluorocyclobutane – raw mateirals for HFP (hexafluoropropylene) production.

Information on direct fluorination of azeotrope mixture of 1,1,2,2-tetrafluorochloroethane and octafluorocyclobutane is listed in Table 23. One can see, that gas-phase homogenious fluorination (without catalyst) passes in a non-selective way forming tetrafluoromethane, chlorotrifluoromethane, trifluoromethane – products of destructive fluorination of 1,1,2,2- tetrafluorochloroethane and octafluorocyclobutane. Using of non-modified carriers – melted calcium fluoride and aluminium alpha-oxide results in significant increase pentafluorochloroethane’s yield. An interesting fact is, that modifying of α-Al2O3 using copper fluoride, which, as it follows from data presented earlier (Look at Pic, 1) activates fluorine rather weakly, doesn’t result in significant improvement of catalytic qualities of that contact. Modifying of α-Al2O3 using nickel fluoride allowed significant increasing of fluorination selectivity (up to 80-90%); at that, octafluorobutane doesn’t react.

H(CF2)3Cl, H(CF2)4Cl and H(CF2)8Cl Fluorination.

The fluorination of relatively high-boiling (compare to 1,1,2,2-tetrafluorochloroethane) α-hydro-ω-chloroperfluoroalkanes1 goes, as test showed more selectively (Refer to Table 24).

Table 24. Direct Catalytic Fluorination of H(CF2)3Cl, H(CF2)4Cl and H(CF2)8Cl (volume rate of input - 100 hour-1, mole rate fluorine: substrate = 1,5).

|

# |

Catalyst |

Temperature, K |

Substrate |

|||||

|

H (CF2)3Cl |

H (CF2)4Cl |

H (CF2)8Cl |

||||||

|

Conversion,% |

Yield C3F7Cl, % |

Conversion,% |

Yield C4F9Cl% |

Conversion,% |

Yield C8F17Cl, % |

|||

|

1 |

α-AI2O3 |

413 |

12 |

83,7 |

15 |

99,1 |

- |

- |

|

2 |

-«- |

433 |

20 |

82,4 |

23 |

97,8 |

28 |

98,6 |

|

3 |

-«- |

453 |

35 |

82,0 |

48 |

97,1 |

62 |

98,0 |

|

4 |

-«- |

473 |

68 |

81,5 |

93 |

96,0 |

94 |

97,4 |

|

5 |

NiF2/α-AI2O3 |

373 |

10 |

98,8 |

14 |

99,7 |

- |

- |

|

6 |

-«- |

393 |

20 |

98,0 |

24 |

98,7 |

- |

- |

|

7 |

-«- |

413 |

42 |

97,7 |

48 |

98,2 |

- |

- |

|

8 |

-«- |

433 |

88 |

97,3 |

90 |

97,8 |

94 |

>99,9 |

|

9 |

-«- |

453 |

97 |

96,8 |

98 |

97,4 |

98 |

98,7 |

1They are also the waste products of TFE production.

These data clearly illustrate the catalytic influence of coated nickel fluoride; indeed, the conversion grade (e.g. the fluorination rate) of substrate over catalyst of NiF2/α-AI2O3is much higher under comparable conditions, than over unmodified α-AI2O3. Here we shall also note, that interaction of H(CF2)nCl (n=3ч8) and undiluted fluorine over catalyst of NiF2/α-AI2O3 is characterized by practically quantitive yield of selective fluorination corresponding produts.

Chloroperfluoroalkanes obtained based on TFE production waste can be turned into corresponding perfluoroalkylfluorosulphates (when treating them with chlorine fluorosulphate), and further into fluoroanhydrides and perfluorocarbonic acids /187 – 189/; particularly, perfluoroheptanoic acid – an effective emulsifier used for production of polymers can be synthesized based on chloroperfluoroheptane.

2.5. Unsaturated and Hydrogen Containing Polyfluorinated Compounds Removal From Perfluorocarbon Liquids Using Catalytic Gas-Phase Fluorination

As it has been mentioned before, the treatment of corresponding hydrocarbons using “soft” fluorinating agent – cobalt trifluoride has been laid as a basis of our obtaining technology for a wide class of perfluorocarbonic liquids; fluorocarbonic liquids (raw material) forming at that contain significant amounts of unwanted admixtures – hydrogen containing and unsaturated polyfluorinated compounds. In the present part of work the results on studying the opportunity of fine purification of fluorocarbonic liquids raw materials from polyfluorinated admixtures during their thermal treatment in gaseous phase using “hard” fluorinating agent – elemental fluorine in the layer of NiF2/α-Al2O3 – an effective catalyst of direct fluorination of both hydrogen containing and unsaturated fluororganic compounds.

2.5.1. Fluorination of Raw Perfluorodimethylcyclohexane.

Perfluorodimethylcyclohexane (PFDMCH) is a promising fluorocarbonic liquid in terms of nanotechnologies. Besides that, the liquid is an effective dielectric and is used contemporary aviation technics. In /190,191/ the quality demands for PFDMCH are formulated, which, in particular, suppose a high purity of a finished product – the concentration of partially fluorinated admixtures must not exceed 40 mg/kg (in terms of detached ion-fluorine).

The known technology of PFDMCH contains thermal fluorination of dimethylbenzene (meta-xylol) by cobalt trifluoride, purification of raw PFDMCH e.g. removing of partially fluorinated compounds using acetone extraction, isolation of PFDMCH by rectification, which again undergoes multiply washing with acetone for the purpose of final removal of partially fluorinated admixtures from it.

The main disadvantages of this technology are:

- low quality of PFDMCH caused by unfinished removal of partially fluorinated admixtures during acetone extraction – their resudial content exceeds the permissible concentration more than 10 times (40 mg/kg);

- low productivity and high labour intensiveness of the stage of multiply extraction using acetone;

- relatively low yield of target product caused by forming of large quantities of unutilizable partially fluorinated compoinds;

- fire- and explosion safety caused by using of acetone;

- environmental pollution.

All these disadvantages are avoidable if we carry out the purification of raw PFDMCH by selective gas-phase catalytic fluorination using elemental fluorine; indeed, such setting of technology would allow increasing of target product purity due to lowering of residual content of partially fluorinated admixtures and utilizing of polyfluorinated dimethylbenzene derivatives obtaining target product – PFDMCH, as well as saying no to use of inflammable and explosive acetone, thus totally eliminating its dumping.

Information on catalytic fluorination of raw PFDMCH on laboratory and pilot scale is listed in Table 25; here as well, the results obtained during fluorination of raw product in an empty reactor with no catalyst are liste for you to compare.

From the data listed here one can see, that fluorination of raw PFDMCH using diluted fluorine in an empty reactor without catalyst at 570-620 K is characterized by low removal/purification grade from partially fluorinated compounds, which is at the level of 40-50% (experiments 1, 2 Table 25); at that, the process is going in a non-selective way forming large quantities of destruction and carbon-black products. The raw product after being treated with fluorine in an empty reactor gets its characteristic yellow colour.At temperature range over 620 K a sharp increase of destructive fluorination input occurs.Using of undiluted fluorine during fluorination in an empty reactor is rather complicated as in this case the process becomes explosive in a whole studied range of temperatures.

Table 25. Direct Fluorination of Raw Product of PFDMCH 1(volume rate of input -140 hour-1)

|

# |

Catalyst |

Temperature, K |

Fluorine Conversion Grade, % |

Substrate Destruction Grade,% |

Concentration of partially fluorinated Admixtures, mg/kg |

Grade of Purification from partially fluorinated Admixtures, % |

|

Laboratory experiment results (mole rate PFDMCH:fluorine = 5,3) |

||||||

|

1 |

Without catalyst |

573 |

17 |

4,2 |

6020 |

52,8 |

|

2 |

-«- |

623 |

51 |

5,3 |

7580 |

40,6 |

|

3 |

Cu, metall |

573 |

26 |

0,8 |

3700 |

71,0 |

|

4 |

-«- |

623 |

42 |

2,4 |

4800 |

62,4 |

|

5 |

α-Al2O3 |

573 |

16 |

0,2 |

98 |

99,2 |

|

6 |

-«- |

623 |

21 |

0,2 |

62 |

99,5 |

|

7 |

-«- |

673 |

22 |

0,4 |

37 |

99,7 |

|

8 |

-«- |

723 |

24 |

0,5 |

24 |

99,8 |

|

9 |

NiF2/α-Al2O3 |

573 |

24 |

0,1 |

50 |

99,6 |

|

10 |

-«- |

623 |

28 |

0,1 |

34 |

99,7 |

|

11 |

-«- |

673 |

32 |

0,2 |

18 |

99,9 |

|

12 |

-«- |

723 |

35 |

0,4 |

12 |

>99,9 |

|

Results of pilot experiments (mole rate PFDMCH:fluorine = 1,4) |

||||||

|

13 |

NiF2/α-Al2O3 |

573 |

- |

0,1 |

70 |

99,2 |

|

14 |

-«- |

573 |

- |

0,2 |

73 |

99,2 |

|

15 |

-«- |

623 |

- |

0,2 |

47 |

99,5 |

|

16 |

-«- |

623 |

- |

0,2 |

48 |

99,5 |

|

17 |

-«- |

673 |

- |

0,3 |

15 |

99,8 |

|

18 |

-«- |

673 |

- |

0,2 |

13 |

99,9 |

1Initial raw product of PFDMCH contained partially fluorinated compounds in a quantity (in terms of detached ion-fluorine) 12770 mg/kg (experiments 1-12) and 9130 mg/kg (experiments 13-18). In experiments without catalyst fluorine was diluted with nitrogen (up to 25 volume %), in other experiments undiluted fluorine was used.

Using of known catalyst – metallic copper nozzle allows applying undiluted fluorine; at that, though the purification/removal grade from partially fluorinated admixtures doesn’t exceed 75% it somewhat increase compare to fluorination in empty reactor (experiments 3-4, Table 25).

At temperatures above 620 K the fluorination in the layer of metallic copper is characterized by sharp increase of the raw material destruction grade and decrease of the purification/removal totalness from polyfluorinated admixtures.

Studying of raw product of PFDMCH at α-Al2O3 and NiF2/α-Al2O3 revealed significant increase of purification grade(experiments 5-12, Table 25), which significantly grows with temperature increase (99,9% and more).

Fluorination even under rather severe conditions (720 K, undiluted fluorine) goes in a rather selective way – thus, the raw materials destruction grade at NiF2/α-Al2O3 doesn’t exceed 0,4 %.

Comparison of data obtained using α-Al2O3 and NiF2/α-Al2O3 (experiments 5-12, Table 25) indicates significant catalytic influence of dispersed nickel fluoride – residual content of partially fluorinated admixtures at this catalyst can be lowered to 10-20 mg/kg; purification grade at that exceeds 99,9 %.

Data on direct fluorination of raw product of PFDMCH in the layer of NiF2/α-Al2O3 at pilot plant (13-18, Table 25) indicates high effectiveness of catalytic method of removal and good reproduction of results at enlargement of fluorination scale.

We shall note, that listed results are laid as a base of developed by us and introduced technology of high purification PFDMCH, which includes thermal processing of dimethylbenzene using cobalt trifluoride, direct catalytic fluorination of formed raw product at NiF2/α-Al2O3and rectification isolation of target product /192/; PFDMCH produced according to that technology meets the claimed demands by all the showings (ТУ-044-13-85).

2.5.2. Fluorination of Perfluorocarbon Liquids and Lubricants (PFCL and L) Raw material.

The technology of perfluorocarbonic liquids of B-1*, M-1*, lubricants UPI*, KS* and KST*, perspective liquids for nanotechnologies as well as PFDMCH technology contains thermal fluorination of corresponding hydrocarbons (in this case – the fraction of transformer/insulating oil) using cobalt trifluoride, purification of forming raw product from partially fluorinated compounds using multiple extraction by acetone and its fraction distillation at lowered pressure isolating target products. PFCL and L obtained in such way are of low chemical resistance caused by the concentration of significant amounts of partially fluorinated admixtures – for example, they are totally destroyed even at short-term contact with 10-% aqueous solution of sodium hydroxide (350K).

*-trademarks of OJSC HaloPolymer (Russia),

The fluorocarbonic liquids quality improvement can be achieved, as it has been mentioned before, if they are purified using method of catalytic fluorination (instead of extraction by acetone); such setting of technology would allow refusing of fire hazardous and explosive acetoneusing, as well as increasing the yield of target products due to utilization of polyfluorinated (so called “acetonesolubale”) admixtures, which concentration in the raw product is rather big and amounts to 12-15%.

Information on direct gas-phase fluorination of raw product of PFCL and L is listed in Table 26.

The process carrying out in an empty reactor (without catalyst) is accompanied by non-selective destructive fluorination even at diluting fluorine with nitrogen. Fluorination over metallic copper catalyst also passes in a non-selective way (experiments 1-3, Table 26).

Using unmodified α-Al2O3 allows achieving of raw product’s fine purification from partially fluorinated admixtures (the grade of purification reaches 99,2%); at the same time in a number of cases (refer to experiment 5 Table 26) they have observed sharp decrease of the process selectivity when using this contact.

Using nickel fluoride as a catalyst applied onto α-Al2O3, allowed significant increasing of PFCL and L product purification/removal grade from partially fluorinated admixtures (up to 99,9% and above) as well as stabilizing selective fluorination by undiluted fluorine.

Thus, in this case the use of NiF2/α-Al2O3 allows solving the problem of selective fluorination.

Table 26. Direct Fluorination of Raw Product of PFCL and L1 (temperature – 673 K, reactor’s volume – 50 ml, raw product input rate – 50 g/hour).

|

# |

Catalyst |

Fluorine Input Rate, g/hour |

Fluorine Conver sion Grade, % |

Raw Material destructtion Grade, % |

Partially fluorinated Addmixtures Concentration mg/kg |

Grade of Purification from partially fluorinated Addmixtures % |

|

1 |

Without catalyst |

3,3 |

>99 |

24 |

15600 |

- |

|

2 |

-«- |

4,4 |

>99 |

22 |

15000 |

- |

|

3 |

Cu, metal |

3,7 |

>99 |

17 |

7100 |

25,3 |

|

4 |

α-Al2O3 |

3,5 |

71 |

6 |

75 |

99,2 |

|

5 |

-«- |

4,4 |

>99 |

14 |

3700 |

61,0 |

|

6 |

NiF2/α-Al2O3 |

3,4 |

73 |

4 |

54 |

99,4 |

|

7 |

-«- |

4,0 |

68 |

3 |

6 |

>99,9 |

|

8 |

-«- |

4,0 |

64 |

3 |

5 |

>99,9 |

1Initial raw product contained partially fluorinated compounds in amount of 9500 mg/kg (in recalculation per detached ion-fluorine). In experiment 2 nitrogen was being poured into reactor at a rate of 6 l/h; in all other experiments undiluted fluorine was used.

It is interesting to note, that carrying out the purification of PFCL and L product using catalytic fluorination allows decreasing of partially fluorinated admixtures residual content by a factor of hundred compare to using of extraction by acetone. That fact indicates significant improvement of quality of target products, which reveals itself, particularly, in increasing of their chemical stability; thus, raw product after catalytic processing with fluorine endures even a prolonged heating up (375 K) with 40 % solution of sodium hydroxide. Improving quality of perfluorocarbonic liquids and lubricants can result in increase of their service life as well as open new fields for their application.

Conducted at industrial reactor experiments (NiF2/α-Al2O3 catalyst’s amount - 6,2 dm3) fully confirmed the results of laboratory experiments.

Method of catalytic fluorination opens wide opportunities for sharp (two times) increase of production of deficit PFCL and L in their existing production. The icrease of productivity can be achieved, as pilot plant experiments proved, due to trivial increase of hydrocarbons input rate at fluorination using cobalt trifluoride at existing agregates of ongoing operation with further utilization of intensively forming partially fluorinated compounds in this case (35-38%) by selective catalytic fluorination using elemental fluorine /193/.

Thus, using of selective gas-phase fluorination when purifying raw product of PFCL and L from undrfluorinated compounds (instead of extraction by acetone) allows:

- significant improving of target products quality at account of sharp increase of totalness of their purification;

- increasing of target products yield at account of utilization of partially fluorinated (“acetone solubale”) compounds containing in raw product.

- increasing dramaticallythe capacity of existing production;

- solving the problem of waste products regeneration;

- increasing the production fire safety and decreasing the environment due to total exclusion of acetone from technology.

2.5.3. Fluorination of Perfluorodecaline Raw Product

Technology of producing of Perfluorodecaline (PFD) – perspective fluorocarbonic liquid for nanotechnologies and main component of artificial blood substituent includes thermal fluorination using cobalt trifluoride, condensation of PFD raw product, its purification from partially fluorinated compounds by gase phase homogenious fluorination using diluted elemental fluorine, fine purification from partially fluorinated admixtures using processing with aqueous alcoholic solution of potassium hydroxide and rectification /194/.

A relatively low degree of PFD raw product purification from partially fluorinated compounds during its gas-phase fluorination using diluted fluorine and low productivity of fluorination unit are the disadvantages of this technology. In this connection the studying of catalytic fluorination of PFD raw product was of interest; data is presented in Table 27.

Table 27. Direct Fluorination of PFD Raw Product1 (temperature – 673 K).

|

# |

Catalyst |

Volume rate of Input2, hour-1 |

Mole rate PFD:Fluorine |

PFD Destruction Degree, % |

Concentration of partially fluorinated Admixtures mg/kg |

Purifcation Degree from partially fluorinated Admixtures, % |

|

|

1. Laboratory experiments Results |

|||||||

|

1 |

Without Catalyst |

65 |

2,1 |

0,2 |

1312 |

94,2 |

|

|

2 |

-«- |

95 |

2,1 |

1,9 |

1628 |

92,8 |

|

|

3 |

α-AI2O3 |

130 |

1,9 |

<0,1 |

241 |

98,9 |

|

|

4 |

NiF2/α-Al2O3 |

100 |

7,2 |

<0,1 |

15 |

99,9 |

|

|

5 |

-«- |

110 |

3,3 |

<0,1 |

5 |

>99,9 |

|

|

2. The Results of Pilot experiments |

|||||||

|

6 |

Without catalyst |

40 |

1,2 |

0,8 |

91 |

99,0 |

|

|

7 |

-«- |

65 |

1,2 |

1,4 |

310 |

96,7 |

|

|

8 |

-«- |

65 |

1,2 |

burning (carbon black, yellow product) |

|||

|

9 |

NiF2/α-Al2O3 |

65 |

1,2 |

0,3 |

6 |

>99,9 |

|

|

10 |

-«- |

105 |

1,2 |

0,4 |

8 |

99,9 |

|

|

11 |

-«- |

130 |

1,5 |

0,4 |

17 |

99,8 |

|

|

12 |

-«- |

200 |

1,4 |

0,4 |

34 |

99,6 |

|

1The initial PFD raw product contained partially fluorinated compounds in amount of (in terms of detached ion-fluorine) 22670 mg/kg (experiments 1-5) and 9450 mg/kg (experiments 6-12). In experiment without catalyst fluorine was diluted with nitrogen to 15 volume % (experiments 1, 2, 6, 7) and to 30 volume % (experiment 8); in other experiments undiluted fluorine was used.

2Nitrogen input is not taken into account (was put into in experiments with no catalyst).

It is typical, that homogenious selective fluorination (without catalyst) can be carried out only when fluorine is diluted with nitrogen – otherwise the fluorination is accompanied by raw materials destruction and decrease of purification degree.

The opportunity to use undiluted fluorine is a specific feature of fluorination in the layer of α-AI2O3 and nickel fluoride applied onto α-AI2O3, at that the process is going selectively and is characterized by sharp drop of residual content of partially fluorinated compounds – approximately by a factor of hundred compare to the homogenious fluorination (experiments 1-5, Table 27). Such a sharp increase of the purification degree is obviously a consequence of both fluorine activation (in case of NiF2/α-AI2O3) and growth of concentrations of reacting components (fluorine and partially fluorinated admixtures) and contact period when excluding the nitrogen input into the reaction zone.

Pilot experiments fully confirmed the results of laboratory studies (experiments 6-12, Table 27) and they show a significant increase of purification degree and reactor’s productivity when fluorinating in the layer of catalyst NiF2/α-Al2O3 using undiluted fluorine.

The method of PFD raw product cathalytic fluorination is introduced in its production.

Results listed in the present work totally conform the facts /195 – 209) and allow drawing out a wide range of promising studies in the field of direct fluorination.

Thus, the carried out complex study of fluorination of wide range of unsaturated and hydrogen containing polyfluorinated organic compounds using elemental fluorine allowed creating scientific basics for selection of catalysts for their selective carrying out and selecting a universal catalytic composition - NiF2/α-AI2O3, which is highly active, selective and stable.

3. Catalysis of Polyfluorinated Organic Compounds’ Thermal Transformations. Aggression Resistant Catalysts Based on α-Al2O3

3.1 New Perspectives for Creating of Aggression Resistant Catalysts of Polyfluorinated Organic Compounds’Thermal Transformations

High reactive activity of medium caused by formation of aggressive products (hydrogen chloride, hydrogen fluoride, carbonyl difluoride etc.) as it has been mentioned before is a specific feature of thermal transformations of fluoroorganic compounds. This fact must be taken into account when developing catalysts of thermal transformations of polyfluorinated compounds (PoFC), which must be stable/resistant to the effect of initial compounds and reaction products even at high temperatures; chemical interaction of catalysts and components of reaction mixtures is as a rule accompanied by phase transfers, which result in sharp decrease of mechanical durability and decomposition of heterogeneous contacts.

Deep fluorination of γ-Al2O3when using catalysts based on it for direct fluorination of organic compounds is a demosnrative example of such interaction; the corresponding phase transfer as it has been mentioned earlier results in mechanical decomposition of that catalysts.

The analysis of articles regarding creaction of effective catalysts for thermal transformations shows, that applying of compositions chemically inert towards components of reaction mixtures under the conditions of a certain process is the main method providing stability for heterogeneous contacts. The nature of contrion at active centres of catalyst, which as a rule are metals’ cations is defined at that by the nature of reagents. Thus metals oxides /210/ are used most often to intensify the oxidation by oxygen, metals sulfides /211/ are used to carry out the transfromations of sulphur organic compounds, metals nitrides and hydrides /212/ are used to activate the molecular nitrogen and hydrogen, metals chlorides and fluorides /213,214/ are used to catalyze thermal transformations of chlorine- and fluororganic compounds respectively.

Catalysts created without taking into account of these particularities are of lowered stability and, as a rule, they have got a limited, narrow operational temperature interval. Thus, the attempts of industrial use of metallic nickel, copper or chrome tp oxidate hydrocarbons or ammonia appeared to fail, particularly, due to oxidation of metals and their gradual decoposition /215/.

In /73/ it is being noticed, that temperature of direct fluorination of organic compounds at metallic catlysts must not exceed 600 K; otherwise, there is a deep fluorination of metals going on as well as their decomposition.

Even more seldom stability of catalysts is provided by their specific resistance to components of reaction mixtures; thus, the metallic platinum, which doesn’t form oxides and decompose during exploitation is the most stable catalyst of high temperature (1100-1200K) selective oxidation of ammonia using oxygen /216/.

As we have showed, its exteremely high resistance/stability in fluorinating media (it doesn’t decompose in elemental fluorine even at 920K) is a specific feature of α-Al2O3. Using of stable catalysts based on α-Al2O3allows, as it has been shown above, sharp increasing (compare to known catalysts)of selectivity and rate of direct fluorination of polyfluorinated organic compounds. Besides that, α-Al2O3 isquite available, cheap and widely produced (in different modofications) by Russian industry /217/. All this opens up the new perspectives of creation of effective aggressive resistant catalysts of thermal transformations of polyfluorinated organic compounds based on α-Al2O3.

In the present section the reslts of studies regarding catalysis of thermal dechlorination of fluorochlorocarbones using hydrogen and terafluoroethylene oxidation are listed.

3.2 Fluorochlorocarbons’ Dechrolorination by Hydrogen.

Fluorocarbones dechlorination is one the main methods of fluorolefines synthesis – raw material to obtain fluoroplastics, fluororubbers and a whole number of other practically important fluororganic products. Fluorochlorocarbones’ dechlorination technology is now based on using expensive and deficit metallic zinc and it is characterized by low productivity, high metallic capacity and environmental congestion with toxic zinc chloride. All of these drawbacks can be avoided by using molecular hydrogen as a dechlorinating agent.

At the same time a relatively high temperature (600K and above) is needed for dechlorination of fluorochlorocarbones using hydrogen over catalysts, that leads to side reactions going on. In this connection the development of active and stable catalytic systems providing selective dechlorination of fluorochlorocarbones using hydrogen is actual.

3.2.1 Analytical Review. Fluorolefines’ Obtaining by fluorochlorocarbons’ hydrogen dechlorination

Catalytic dechlorination of 1,1,2-trifluorotrichloroethane (R-113) using hydrogen is one of the most fully described.

The only example of carrying out this process over the absence of catalyst is listed in /218/, where heated iron tube was used as a reactor. At 820-870 K and contact period of 1-2 sec the conversion degree of R-113 amounted to 24-36%, and the yield of trifluorochloroethylene - 60-84%. Trifluorodichloroethane (R-123) and tetrafluoroethylene are formed as by-products.

For the first time the obtaining of fluorochlorocarbones by catalytic dechlorination using hydrogen was described by the authors /219/; copper (5-10%) applied onto charcoal and silicagel was used as catalyst, and 1,2-dichlotetrafluorethane, 1,1,2-trifluorotrichloroethane, 1,2-difluorotetrachloroethane, 1,1-difluorotetrachloroethane and 1,2-dichlorohexafluorocyclobutane were used as substartes. The conversion degree of 1,1,2-trifluorotrichloroethane and the yield of trifluorochloroethylene over Cu/SiO2catalyst at 730-750K and contact period of 10 seconds amounted to 50% and 74-79% respectively.

It is also noted, that metallic copper is less active, than the applied one; increasing temperature up to 870K was required here to achieve comparable conversion degrees.

Dechlorination of 1,2-difluorotetrachloroethane passes under milder conditions (640-660K); the yield of 1,2-difluoroethylene is 90% for reacted (72%) substrate /219/. The conversion degree of non-symmetrical isomer – 1,1-difluorotetrachloroethane is significantly lower under the same conditions (only 20%). The using of nickel, cobalt, platinum and palladium 1,1,2-trifluorotrichloroethane applied onto activated carbon is described in /220-222/.

Maximum yield of trifluorochloroethylene (75%) has been reached using nickel containing catalyst at 700-750K, contact period of 2,5 sec and mole ratio hydrogen : R-113 equal to 1,3.

It is being noted /223/, that using of calcium and barium phosphates, chlorides and fluorides as catalytic carriers doesn’t result in rising (compare to activated carbon) of catalysts’ effectiveness. Thus, when using these carriers modified by nickel the trifluorochloroethylene yield amounted to 20-40% at 670-750K and contact period of 4,5 seconds.

Also the activity decrease of these catalysts is being noted: fast (in 2-3 hours) – due to forming of nickel fluorides and chlorides, and slow (in 30 hours) – as a result of densinty products forming on the surface.

In /224/ a wide range of catalysts of 1,1,2-trifluorochloroethylene dechlorination using hydrogen is described (active components – copper, cobalt, silver or platinum, carriers – active aluminium oxide, activated carbon, glass necklace or magnesium fluoride). Maximum yield of trifluorochloroethylene – 96,7% has been reached at R-113 conversion degree of 65% using magnesium fluoride modified by copper and cobalt (mole ratio of components Co:Cu:MgF2= 1:30:150) at 734 K, contact period of 2-3 sec and ratio of substrate:hydrogen equal to 1. Using of magnesium oxide as a carrier results in some decrease of selectivity (to 93%); the raw material conversion degree remains the same at that. It is also being noted /224/, that dechlorination of fluorochlorocarbones at temperature above 870K is undesirable due to selectivity decrease and lowering of catalyst run; catalyst can be regenerated by oxygen containing gas, for example, air at 580-950 K.

In /225/ the trifluorochloroethylene obtaining method by dechlorination of 1,1,2-trifluorotrichloroethane at calcium fluoride modified by chromium oxide as well as copper or nickel is described.

At 620-670 K and contact period of 10 seconds the conversion degree of substarte at Cu,Cr2O3/CaF2 catalyst amounted to 35-40%; at that trifluorochloroethylene was virtually the only products of reaction. Optimal mass ratio of Cu:Cr2O3:CaF2 at preparing the catalyst from nitrates amounts to 30:15:55. It is being noted /225/, that catalyst containing only chromium oxide and calcium fluoride is unactive under these conditions.

At the same time the chromium oxide applied onto chips from alundum or melted aluminium oxide can be used as it follows from /226, 227/ as a catalyst of 1,1,2-trifluorotrichloroethane dechlorination; conversion of raw materials and yield of trifluorochloroethylene at 798 K and contact period of 15 seconds amounted to 24,5 and 73%, respectively. Increased time of catalyst operation to regeneration is being noted (from 52 to 200 hours). In case of magnesium fluoride modified by chromium oxide the process is carried out at 750-820 K, contact period of 2-15 seconds and in excess of hydrogen (25% of stechiometric quantity); conversion of raw material (35%-40%) and yield of trifluorochloroethylene (50-55%) do not decrease during 30 hours of continiuos operation of catalyst /226/.

In /228/ the dechlorination of 1,1,2-trifluorotrichloroethane at chromium oxide modified by copper and barium oxide has been described. The catalysts are being prepared by co-precipitation of hydroxide from the nitrates solutions of different mass ratio of metals Ba:Cr:Cu – from 1:1,5:1,5 to 1:8:9. The ratio of Ba:Cr:Cu equal to 1:3:3,1 is the optimal one; the yield of trichloroethylene and the conversion degree at such catalyst amounted to 85 and 60% respectively (temperature 648 K, contact period 9 sec, mole ratio hydrogen:R-113=1,2) It is being noted /228/, that the carrying out the reaction at temperature above 700 K is accompanied by the transfer of chromium oxide into catalytically inactive form.

In /229/ the data on dechlorination of 1,1,2-trifluorotrichloroethane at activated carbone, magnesium fluoride, chamotte and firebrick modified by copper, nickel, cobalt and iron are listed. Maximum yield of trifluorochloroethylene – 60-75% at conversion of R-113 of 54-83% has been achieved at iron containing catalysts (770-800 K, contact period – 4-10 seconds).

In /230/ the results on 1,1,2-trifluorochloroethane using hydrogen at potassium-magnesium fluoride (NaMgF3) are listed – the yield of trifluorochloroethylene and conversion degree of 1,1,2-trifluorotrichloroethane at 773 K amounted to 83,9 and 21,3% respectively.

Modifying of potassium-magnesium fluoride using nickel, copper and iron leads to significant increase of catalytic activity as it is noted in /230/ and allows putting down the process temperature; thus, during dechlorination in the layer of copper containing contact (6,3 mass.% copper, 748 K) the conversion degree of 1,1,2-trifluorotrichloroethane amounted to 35,6%, and the yield of trifluorochloroethylene - 85,2%.

Modifying of potassium-magnesium fluoride using palladium (0,5 mass.%) leads to sharp increase of catalysts activity /230/, that allows to lower the temperature to 470 K; at that a significant change in activity of dechlorination selectivity takes place – trifluoroethylene is the main reaction product. In /230,231/ they also point out the high catalytic activity of metallic palladium at 470-570 K in dechlorination of trifluorochloroethylene by hydrogen to trifluoroethylene.

In /232/ you can find the detailed description of recipe and method to prepare oxide aluminium molibden catalyst and an opportunity of its use to dechlorinate R-113 using hydrogen obtaining trifluorochloroethylene is noted as well.

The review of works on dechlorination of 1,2-dichlorotetrafluoroethene (R-114) using hydrogen demonstrates, that the same types of catalysts that are used at dechloriantion of R-113 are usedhere. Thus, in /233,234/ the use of mixture of copper, barium and chromium oxides is described; the catalyst is being prepared by co-precipitation of copper and barium hydroxide with ammonium chromate, the forming complex is being heated through at 623 K and processed with hydrogen at temperature up to 698 K. The conversion degree of 1,2-dichlorotetrafluoroethane and the yield of tetrafluoroethylene at such catalysts under optimum conditions (650-720 K, contact period 5-10 seconds, mole ratio substrate:hydrogen – 0,75-1,25) amount to 20-25% and 60-65% respectively.

It is being noted, that alkaline earth metals fluorides, magnesium, aluminium and silicium oxides can be used as carriers for copper-chromium oxide catalysts.

In /235/ the data on degalogenation of fluorohalocarbones containing 2-8 carbon atoms using hydrogen at aluminium fluoride modified by copper, rhodium, platinum and chromium oxide are listed. Ceolites and active aluminium oxide were used as carriers for a number of catalysts. During dechlorination of 1,2-dichloroethane for example at aluminium oxide modified by copper and chromium oxide (673 K, contact period 60 seconds, mole ratio R-114:hydrogen=1), the yield of tetrafluoroethylene amounted to 61% and the subsrate conversion – to 31%.

Also the iron group metals phosphates applied onto γ-Al2O3 /236,237/ are offered as catalysts for dechlorination of fluorochlorocarbones containing 2-10 carbon atoms; the amount of metal is usually no less than 3% of catalyst weight.

The catalyst is treated with mixture of nitrogen and anhydrous hydrogen fluoride (mole ratio N2:HF=1) at 406 K before the reaction. Nickel containing catalysts are most effective; thus, at dechlorination of 2,3- dichlorooctafluorobutane at nickel oxide modified by nickel phosphate (926 K), perfluorobuten-2 of 88% yield had been obtained at the fluorochlorocarbon conversion degree of 92% /236/.

A two-stage catalytic method of degalogenation of fluorohalocarbons containing 2-10 carbon atoms is described in /238/. At first stage of fluorohalogenating the substarte is put into contact with hydrogen at catalyst containing iron group phosphates applied onto fluorinated γ-Al2O3 at 480-700 K pressure ranging from 9,8*104 to 2,0*106 Pa. The amount of metal phosphate in catalyst in terms of metal is 0,1-10,0 mass.%, the amount of fluorine in carrier– 50-68 mass.%.

The reaction mixture forming at first stage is put into contact (at 480-700 K) with catalytic composition containing oxides and chlorides of cobalt, nickel, zinc, chrome and iron as well as barium chloride at the carrier made of activated carbon or aluminium oxide and fluorolefines of low by-products content are obtained. Thus, during dechlorination of 1,2-ichlorotetrafluoroethane over fluorinated aluminium oxide modified by nickel phosphate (588 K, contact period of 12,5 seconds) and following contacting of reaction gases with barium chloride applied onto activated carbon (673 K, contact period of 180 seconds) tetrafluoroethylene was obtained with the yield of 71,2% (in a one-stage process its yield equaled to 58,9%). The author /238/ supposes, that increasing of yield of target product when using two-stage method is caused by transformation of by-products (1,1,2,2-tetrafluorochloroethane and 1,1,2,2-tetrafluoroethane) at second stage forming tetrafluoroethylene.

The obtaining of hexafluoropropylene by catalytic dehydrochlorination over hydrogen is described in /239/. The process is being conducted inside nickel tube at 650-750 K in the layer of alkaline and alkaline earth metal modified by copper, nickel and chromium oxide. The yield of hexafluoropropylene at a contact period of 2,5 sec and substrate:hydrogen ratio equal to 1 amounted to 94% and the substrate conversion degree – 56%.

In /240/ data on dechlorination of 1,1-difluoro-1,2-dichloroethane on nickel spirals are listed; at 720-870 K, mole ratio substrate:hydrogen equal to 1,25 and contct period of 10 seconds the yirld of 1,1-difluoroethylene exceeded 99%, and the substrate conversion degree was 40-45%.

Thus, applied catalysts are used to intensify the dechlorination of fluorochlorocarbones using hydrogen. As a rule, nickel, cobalt, copper and chromium oxide are their active components, and activated carbon, silica gel, ceolites, active aluminium oxide, aluminium, calcium and magnesium fluorides are their carriers.

Dechlorination selectivity of 1,2-difluorotetrachloroethane, 1,1,2-trifluorotrichloroethane and 1,2-dichlorotetrafluoroethane at these catalysts is at the level of 90, 75-85 and 60-65%, respectively.

3.2.2. 1,2-Dchlorohexafluoropropane dechlorination

1,2-dichlorohexafluoropropane (R-216) is a multitonnage waste product of tetrafluoroethylene production and undergoes thermal elimination or is thrown into the atmosphere.The dechlorination of R-216 using hydrogen obtaining hexafluoropropylene (HFP) – a key deficit raw material for production of a number of fluoroorganic products (fluoropolymers, fluorocaotchuoc, fluoropolyesters) is one of the ways to utilize it:

Selecting the catalytic carrier was the first stage of development of effective catalyst for dechlorination of 1,2-dichlorohexafluoropropane.There are no messages on dechlorination of 1,2-dichlorohexafluoropropane; we have tested carriers – activated carbon, active aluminium oxide, aluminium, magnesium and calcium fluorides, which are widely used to prepare catalysts of one type dechlorination processes PoFC /225-240/. Besides that, we have tested α-Al2O3for the first time for this type of reaction, as it has been already mentioned it is highly resistant in agressive fluorinating media.

It’s typical, that known carriers containing silicon oxide (silica gel, amorphous aluminium silicate, ceolites), and based on them catalysts are decomposing as well as experiments proved in the first hours of operation, which can be explained by the presence of anhydrous hydrogen fluoride active towards silicon oxide, which is one of the reaction by-products.

Information on catalytic properties of crriers is listed in Table 28 (experiments 2-8); here the results on non-catalytic interaction between 1,2-dichlorohexafluoropropane and hydrogen are listed as well (experiment 1).

Judging by the listed data one can see, that even in the absence of catalysts the formation of HFP takes place, though the substrate conversion degree is not high and even at 843 K doesn’t exceed 10%. It can also be seen, that at activated carbon and γ-Al2O3 significant amounts of byproducts are formed, and target product yield doesn’t exceed 15%. It is typical, that the chemistry of formation of virtually all byproducts can be explained by disproportionation of the initial 1,2-dichlorohexafluoropropane and dechlorination of disproportionation products using hydrogen (C3F7Cl, C3F5Cl, C3F4Cl2, C3F3Cl3), as well as hydrohalogenation of HFP (C3F7H, C3F6HCl). We will also note, that γ-Al2O3 is decomposing during thermal contacting with R -216 and hydrogen.

Application alkaline earth metals fluorides allows achieving high (over 90%) yield of HFP (experiments 5,6, Table 28): at the same time practical application of these carriers is rather difficult, because even fresh samples are of low mechanical durability. Though melted calcium fluoride is of high mechanical durability, it is characterized by low selectivity and activity (experiments 7, Table 28).

High yield of target product is typical for α-Al2O3 (experiment 8, Table 28); even the prolong presence of this carrier in the reaction zone under rather severe conditions doesn’t influence much its mechanical durability. This result can be explained using data of X-ray phase and chemical analysis of α-Al2O3, and also catalysts based on it after operation, which show the formation only of aluminium fluoride phase trace amounts. On the contrary, its deep fluorination is typical for the catalysts based on γ-Al2O3, and as a consequence loss of mechanical durability.

Thus, testing a wide range of carriers showed, that only α-Al2O3 has got all necessary qualities and it can be used as a carrier for effective catalyst for dechlorination of 1,2-dichlorohexafluoropropane using hydrogen.

Modifying of α-Al2O3 using known active components – chromium oxide, metal cobalt, copper and also nickel results in all cases as it follows from Table 28 (experiments 9-12) and Pic. 3a in increasing (compare to non-modified α-Al2O3) of substarte conversion degree. At that, the catalyst modified using nickel is most active one, and the one modified by chromium oxide is the least active one.

Samples of α-Al2O3 ,modified by cobalt and copper are of intermediate activity. The yield of HFP within the range of 670-770 K is approximately equal at all the catalysts and is at the level of 90 % (the yield at the sample modified by chromium oxide is somewhat lower). At increasing the temperature up to 840 K the yield of HFP at all the catalysts is going downwards.

α-Al2O3, modified by nickel is a rather active and selective catalyst to obtain HFP using dechlorination of 1,2-dichlorohexafluoropropane, what assumes it can be used in practics; at the same time the application of already ready to use commercial heterogeneous contacts at putting the method into practice would have allowed escaping the difficulties connected to setting up a production of a special catalyst.

Due to that we have tested commercial nickel containing catalyst GIAP-3-6H, which is (after thermal processing in the hydrogen medium), applied onto α-Al2O3, and for comparison catalyst NKM-1, which is nickel applied onto γ-Al2O3 (experiments 13-16, Table 28).

Judging by the data listed one can see, that using of catalyst GIAP-3-6H allows achiving virtually quantitive yield of HFP – thus, at 793 K and reagents input rate of 285 hour-1 the yield of C3F6 amounts to 96,3 %, and conversion degree of 1,2-dichlorohexafluoropropane – 90 % (experiment 16, Table 28).

Analogous to it in terms of chemical composition catalyst NKM-1 prepared based on γ-Al2O3 is characterized by significantly lower yield of HFP (experiment 13, Table 28).

Thus, commercial heterogeneous GIAP-3-6H, is an effective catalyst of dechlorination of 1,2-dichlorohexafluoropropane using hydrogen; high yield of HFP at that is backed by using α-Al2O3as catalytic carrier, on surface of which there are no centres, causing the occurrence of side reactions.

Initial data on desiging pilot plant for utilization of R-216 with obtaining of HFP were issued by the results of work.

Pic 3.Temperature dependancies of conversion degrees of (α) 1,2-dichlorohexafluororopane (а) and 1,2-difluorotetrachloroethane (b) while contacting hydrogen at catalysts: 1 – α-Al2O3; 2 – Co /α-Al2O3; 3 – Cu /α-Al2O3; 4 – Ni /α-Al2O3 (volume rate of input of reagents equimolar mixture is 285 hour-1).

3.2.3. 1,2-Ddifluorotetrachloroethane dechlorination

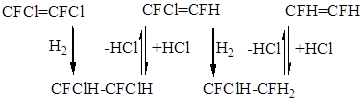

1,2-difluorodichloroethylene is an initial reagent for the synthesis of perfluoromethylvinyl ether – a raw material for the production of new types of fluororubbers and fluoropolymers. Catalytic dechlorination of 1,2-difluorotetrachloroethane using hydrogen is one of the ways to obtain 1,2-difluorodichloroethylene:

![]()

Information on catalytic dechlorination of 1,2-difluorotetrachloroethane using hydrogen is listed in Table 29; here the results on their non-catalytic interaction are listed as well.

It can be seen, that at temperature below 740 K the reaction in the absence of catalyst (tubular quartz reactor) doesn’t occur, substarte’s conversion doesn’t exceed 6% under these conditions. At temperature over 740 K we observe sharp increasing of conversion degree even in the absence of catalyst (experiment 2, Table 29); at that the yield of target product – 1,2-difluorodichloroethylene is not high and is at the level of 60%.

The analysis of data regarding catalytic ptoperties of known carriers (γ-Al2O3; AlF3, activated carbon, MgF2) proves, that γ-Al2O3 is of least selectivity – the yield of 1,2-difluorodichloroethylene in this case doesn’t exceed 2%, and R-113, 114 and tetrachloroethylene are the main products of reaction.

Data regarding catalytic properties of aluminium fluoride (obtained by fluorination of γ-Al2O3 using elemental fluorine), activated carbon and magnesium fluoride proves, that the yield of target product at these carriers is quite high and amounts to 80-90% at conversion degres of 1,2-difluorotetrachloroethane – 70-99% (experiment 5-10, Table 29).

At the same practical application of these carriers is rather complicated. Aluminium and magnesium fluorides are of low mechanical durability and decompose while operating. Activated carbon gradually looses its activity; at the same time the regeneration by high temperature air treatment, which is effective for mineral carriers /224/, in case of activated carbon is absolutely unacceptable.

While testing the carriers a maximum yield of target product had been reached at α-Al2O3 – 94,3 % at full substrate’s conversion (experiment 12, Table 29). Experiments proved, that α-Al2O3 are of high mechanical durability, which isn’t decreasing even at its prolong operation. The absence of forming of products of compacting on its surface which are able of lowering of catalytic activity is a α-Al2O3 characteristic feauture. All of that allows us to consider α-Al2O3the most appropriate carrier for an effective catalyst of 1,2-difluorotetrachloroethane dechlorination, as well as using it as a catalyst in the unmodified form.

It is significant, that the chemistry of forming of practically all of by-products of 1,2-difluorotetrachloroethane and hydrogen interaction, as well as one of 1,2-dichlorohexafluoropropane can be explained by disproportioning of the initial substarte and dechlorination of disproportioning products using hydrogen (C2F5Cl, C2F4Cl2 , C2F3Cl3 , C2Cl4 , C2FCl3, C2FCl5), as well as hydrohalogenation of halolefines forming at that (C2F4ClH, C2F2Cl3H). Besides that, during interaction of 1,2-difluorochloroethylene and and hydrogen chlorine substituting products for hydrogen – 1,2-difluorochloroethylene and 1,2-difluoroethylene in the molecule of 1,2-difluorodichloroethylene are formed (for example, the yield of C2F2H2, in the experiments 2 amounted to 4,2%).

It might be an interesting fact, that α-Al2O3is quite inert, as experiments proved, in the reactions of disproportioning; thus, the conversion degree of 1,2-difluorotetrachloroethane at this carrier in the medium of nitrogen at high temperatures – 843 and 893 K amounted only to 1,2% and 3,2% respectively. At that, in the reaction products 1,2-difluorodichloroethylene and chlorine have been discovered – this indicates the dechlorinating passing in the inert medium. Thus, the role of hydrogen at dechlorination of fluorochlorocarbones at carriers (especially, at high temperatures) can be included in connecting the forming chlorine in corresponding shift of balance of substrate’s dissociation onto fluorolefine and chlorine.

As we can see from the results listed in Table 29 (experiments 13-20) and Pic 3b the modifying of α-Al2O3 using chlorine, cobalt, copper and nickel oxide results in significant growth of activity, which is increasing in the row of Co<Cr2O3<Cu<Ni. For the contacts modified using nickel the total conversion of substrate is observed even at 690 K, copper at 740 K, and cobalt and chromium oxide – only at 790 K.

Contacts modified by chromium oxide are of least selectivity; here 1,1,2-trifluorotrichloroethane and pentafluorochloroethane are the main by-products, which indicates the significant input of substrate’s disproportioning.

α-Al2O3, modified by nickel is of most high selectivity; the yield of 1,2-difluorodichloroethylene is reaching 97,1% at full conversion of 1,2-difluorotetrachloroethane (experiment 19, Table 29). Such high activity and selectivity of Ni /α-Al2O3catalyst inpact create prerequisites for commercial implementing of R-112 dechlorination using hydrogen.

Testing of GIAP-3-6H (Ni/α-Al2O3) commercial catalyst revealed its high activity and selectivity (experiments 23-25, Table 29); the yield of 1,2-difluorodichloroethylene at practically total conversion of substrate had reached 98,5%. NKM-1 nickel containing commercial catalyst prepared on the basis of γ-Al2O3 tested for comparison and analogous by chemical composition is of significantly lower impact selectivity (experiment 21, Table 29) and is decomposing in the course of operation.

Forming of significant quantities of 1,2-difluoroethylene, yield of which had reached 24,8% (693 K) is typical for this catalyst besides by-products listed in Table 29. It is an interesting fact, that the preliminary processing of NKM-1 catalyst using fluorine (743 K) results in significant increasing of its impact selectivity (experiment 22, Table 29).

High mechanical durability, which isn’t decreasing in the course of operation and regeneration is an distinguishing feature of GIAP-3-6H catalyst. Prolonged use of this catalyst is accompanied by decreasing of its activity, which is caused by formation of products of compacting on its surface; air regeneration (770-820 K) results in full restoration of catalytic activity.

For the purpose of increasing 1,2-difluorotetrachloroethane hydrogen dechlorination stability we have tested a double layer catalyst. Unmodified α-Al2O3(80 mass.%) was the first layer, GIAP-3-6H catalyst (20 масс.%) was the second one. Such double layer catalyst demonstrated high activity and selectivity. Thus, at 740-760 K we have observed full conversion of substarte, and process selectivity had reached 97%. Besides that, double catalyst was of high stability. That effect probably, is caused by the fact, that in the first layers, e.g. in place, where carbon-producing goes more intensively α-Al2O3has been used, at which products of compaction do not form.

According to the results of work the initial data for projecting the 1,2-difluorodichloroethylene obtaining technology using dechlorination of 1,2-difluorotetrachloroethane by hydrogen at double-layer catalyst α-Al2O3 – GIAP-3-6H has been issued.

3.2.4. 1,1,2-Trifluorochloroethylene dechlorination

Production of trifluorochloroethylene – a raw material for the synthesis of fluoroplastics and fluororubbers is based on dechlorination of 1,1,2-trifluorotrichloroethane by expensive and deficit metallic zinc and it is characterized by low productivity, high materials consumption, as well as polluting the environment with toxic zinc chloride. Carrying out the dechlorination of 1,1,2-trifluorotrichloroethane using hydrogen we can escape all of these drawbacks:

Data on catalytic properties of known carriers for catalysts of dechlorination of fluorocarbons using hydrogen – γ-Al2O3, activated carbon, aluminium, magnesium fluorides, as well as melted calcium fluoride are listed in Table 30; the results obtained using α-Al2O3 are listed here too, and for comparison – in an empty reactor, without catalyst.

One can see, that even in the absence of catalyst a significant conversion of 1,1,2-trifluorotrichloroethane can be observed; at that, the selectivity of dechlorination is decreasing while the temperature is rising (experiments 1, 2, Table 30). Thus, at 793 and 843K the substrate’s conversion degree was 11 and 88% respectively, and the yield of trifluorochloroethylene – 78,3 and 53,7% respectively. Trifluoroethylene, which yield, for example, at 843 K was 24,8%, was the main by-product at non-catalytic gas-phase interaction of 1,1,2-trifluorotrichloroethane and hydrogen.

The analysis of data obtained using γ-Al2O3 and AlF3 (experiments 3-6, Table 30) shows, that products of disproportioning of initial R-113 – R-115, R-114, R-112 are the main products here, as well as the product of hexachloroethane dechlorination – tetrachloroethylene. The yield of target product doesn’t exceed 0,1%. Besides that, R -122, R-123, R-124 and 1,2-difluorodichloroethylene were discovered in the reaction products.

It is worth noting, that the same products are formed during dechlorination of 1,2-difluorotetrachloroethane.

When using activated carbon as a catalyst the yield of target product id significantly higher and is reaching 89,8% (experiments 7,8 Table 30).

The activity of activated carbon dramatically decreases in time and its regeneration by high-temperature processing using air is unacceptable, which is a significant drawback of activated carbon.

In what follows we have tested magnesium and calcium fluorides. Magnesium fluoride was prepared by pressing of high disperse salt (surface – 12,5 m2/g); that sample was characterized by low mechanical durability. On the contrary, calcium fluoride was rather stable; it was obtained using melting method (surface 0,2 m2/g).

One can see from the Table 30 (experiments 9 – 11), that substrate’s conversion degree is significantly higher at more dispersed magnesium fluoride. Main by-products here are the same as at non-catalytic interaction of 1,1,2-trifluorotrichloroethane and hydrogen – trifluoroethylene and trifluorodichloroethane isomers (R-123); the yield of target product is rather high and is located at the level of 85 - 90%.

The analysis of data obtained using α-Al2O3 shows that application of that carrier allows reaching high yield of trifluorochloroethylene in a wide range of temperatures; thus, a 740-790 K the yield of target product is at the level of 86-91% (experiments 12, 13, Table 30). It is interesting, that the activity of that carrier even in unmodified form is rather high (higher, than one of MgF2and CaF2); we have mentioned earlier, that α-Al2O3 is an effective catalyst for dechlorination of 1,2-difluorotetrachloroethane.

Thus, it was discovered by testing of catalytic carriers, that only melted calcium fluoride and α-Al2O3are of sufficient stable mechanical durability. Modifying calcium fluoride using copper, and especially, nickel results in significant increasing of catalytic activity (experiments 14 -17, Table 30), at that, the yield of target product is 87 – 90%.

α-Al2O3, modified by chromium oxide is characterized by significant formation of R-114 and difluorodichloroethylene; total yield of those by-products reaches 23% (experiments 18,19, Table 30). Application of α-Al2O3 modified using palladium results in significant increasing of trifluoroethylene (experiment 20, Table 30).

α-Al2O3 modified by cobalt at temperature below 740 K is characterized by high selectivity (93-95%); at that, substrate’s conversion degree is low (below 25%). Temperature increasing up to 793 K is accompanied by (experiment 22, Table 30) significant lowering of selectivity (down to 85,7%).

Modifying of α-Al2O3 using nickel results in dramatic increase of catalytic activity at moderate temperatures (690-740 K). Thus, conversion degree of 1,1,2-trifluorotrichloroethane at α-Al2O3 after modifying using nickel increases at 693 K from 2 up to 41%, and at 743 K – from 23 up to 70% (experiments 23, 24 Table 30).

The selectivity of dechlorination at Ni/α-Al2O3catalyst, including commercial sample of GIAP-3-6H (experiments 25, 26, Table 30) is 84-90% at conversion degrees of 1,1,2-trifluorotrichloroethane – 40-90%. For comparison, the yield of target product was only 19,5% (experiment 27, Table 30) at catalyst Ni/γ-Al2O3 (NKM-1) under analogous conditions.

Abrupt increase of 1,1,2-trifluorotrichloroethane dechlorination selectivity (94%) has been recorded while studying catalytic properties of copper modified α-Al2O3(experiments 28-30, Table 30). The initial activity of that catalyst is also rather moderate– substrate’s conversion degree exceeds 99% at fresh samples and temperature over 790 K.

Cu/α-Al2O3particularity is the significant drop of its activity in the course of experiment (compare experiments 29, 30, Table 30). Regeneration using thermal treatment in the air flow, which leads to virtually total recovery of nickel containing catalysts, proved to be low effective for Cu/α-Al2O3. The analysis of composition of that catalyst before and after its use for 48 hours (793K) showed a significant decreasing of copper content (from 9,8 down to 2,8 mass.%). Thus, low stability can be caused by its depleted active component, for example, as a consequence of evaporating in the form of volatile copper chloride. The activity of catalyst can also decrease when applied copper dispersion slides down.

Introducing promoting additives – chromium and barium oxides /225, 228, 233-235,237/ is a famous technique to improve stability of copper containing catalysts of fluorochlorocarbones’ dechlorination using hydrogen.

The analysis of data obtained using Cu,BaO,Cr2O3/α-Al2O3 catalyst prepared by us comes as a proof of significant decrease of process selectivity compare to unpromoted Cu/α-Al2O3 (experiment 31, Table 30), mainly at account of formation of dichlorotetrafluoromethane and difluorodichloroethylene typical for the Cr2O3/α-Al2O3catalyst as well..

In what follows we had prepared and tested Cu,BaO/α-Al2O3catalyst, where only barium oxide had been used as a promoter (2 mass.%).

One can see (experiments 32-35, Table 30), that even at 793 K that sample is characterized by exclusively high selectivity of action reaching 96,1%. Stable activity is established approximately in 2-4 hours after start of operation and it corresponds to substrate’s conversion degree equal to 74-76% at 793 K; using of catalyst during 53 hours did not lead to its activity decrease.

The activity of copper containing catalysts based on melted calcium fluoride, which as well as α-Al2O3 is resistant under the conditions of process carrying out is obviously significantly lower due to small carrier’s specific surface (0,2m2/g), which as a consequence leads to decreasing yield of target product because of high input of low-selective non-catalytic dechlorination of substrate using hydrogen (for example, between the grains of catalyst).

Thus, using of α-Al2O3, which isstable in fluorinating media and has got a rather developed surface(7,5-8,0 м2/г) allowed us to select an effective catalyst for dechlorination of 1,1,2-trifluorotrichloroethane using hydrogen – Cu,BaO/α-Al2O3.

According to the results of work initial data for projecting of semi-industrial plant obtaining trifluoroethylene dechlorinating R-113 using hydrogen have been issued.

3.2.5. Dechlorination of 1,2-dichlorotetrafluoroethane

Catalytic dechlorination of 1,2-dichlorotetrafluoroethane (R-114) using hydrogen is one of promising ways of obtaining tetrafluoroethylene

In Table 31 data on dechlorination of 1,2-dichlorotetrafluoroethane using hydrogen over selected by us effective catalysts of same type processes of dechlorination of Rs-216,-112 and -113 are presented; Ni/α-Al2O3and Cu,BaO/α-Al2O3catalysts common feature is that they both are prepared based on α-Al2O3. Here you can also find the information obtained using nickel dispersed on the surface of known carrier for the catalyst of dehlorination of fluorocrabones – γ-Al2O3/238/.

Table 31. Catalytic Dechlorination of 1,2-dichlorotetrafluoroethane Using Hydrogen (Equimolar Reagents’ Mixture Input Rate – 285 hour-1)

|

# |

Catalyst |

Temperature K |

Conversion Degree of Fluorochlorocarbon, % |

Reaction Products’ Yield, % |

||||

|

C2F6 |

C3F8 |

C4F10 |

C5F12 |

Others |

||||

|

1 |

α-Al2O3 |

823 |

26 |

52,5 |

0,8 |

3,2 |

16,7 |

26,8 |

|

2 |

Same |

873 |

67 |

48,9 |

1,5 |

6,8 |

17,1 |

25,7 |

|

3 |

Ni/α-Al2O3 |

773 |

33 |

64,7 |

1,1 |

3,9 |

12,5 |

17,8 |

|

4 |

Same |

823 |

48 |

61,8 |

2,2 |

5,2 |

14,2 |

16,6 |

|

5 |

Cu,BaO/ α-Al2O3 |

823 |

43 |

75,0 |

1,7 |

4,4 |

8,2 |

10,7 |

|

6 |

Same |

873 |

85 |

65,7 |

1,7 |

4,5 |

8,5 |

19,6 |

|

7 |

NiF2/ γ-Al2O3 |

773 |

62 |

21,5 |

2,6 |

8,4 |

31,7 |

35,8 |

|

8 |

Same |

823 |

78 |

14,7 |

3,5 |

12,4 |

30,5 |

38,9 |

One can see from the data above, that dechlorination of 1,2-dichlorotetrafluoroethane is characterized by lower yield of target product and passes under significantly tougher conditions (compare to Rs-112,-113 and -216). Maximum yield of tetrafluoroethylene (75%) had been reached over catalyst Cu,BaO/α-Al2O3at 823 K; substrate conversion degree amounted to 43% at that (experiment 5, Table 31). Besides tetrafluoroethylene significant amounts of trifluorochloroethylene and difluorodichloroethylene are formed during interaction of R-114 and hydrogen. Also hexafluoroethane, pentafluorochloroethane and terachloroethylene were discovered in reaction gases.

It is rather characteristic, that using of catalyst based on γ-Al2O3 (experiments 7,8, Table 31) results in sharp increase of input of by-processes corresponding decrease of tetrafluoroethylene yield.

3.2.6. Dechlorination of perfluoromethoxy-1,2-dichlorotrifluoroethane.

Catalytic dechlorination of perfluoromethoxi-1,2-dichlorotrifluoroethane using hydrogen is one of options to obtain perfluoromethylvinyl ether – a monomer for synthesis of new types of fluororubbers and fluoropolymers:

Data on catalytic dechlorination of perfluoromethoxi-1,2-dichlorotrifluoroethane can be found in Table 32.