Fluorine Notes, 2011, 74, 3-4

THE IMPACT OF TRACIAL 1.1.3-TRIHYDROPERFLUOROPROPANOL-1 ON TRIBOLOGICAL PROPERTIES OF POLY-ε-CAPROAMIDE

FILLED WITH Na+-MONTMORILLONITE AND GRAPHITE

I.A. Novakov*, N.A. Rakhimova*, A.P. Krasnov**, Y.V. Zubavichus**, S. V. Kudashev*

* Volgograd State Technical University, Russia, 400131, Volgograd, Lenin avenue 28,

E-mail: organic@vstu.ru

**A. N. Nesmeyanov Institute of Organoelement Compounds Russian Academy of Sciences (INEOS RAS),

Russian Federation, 119991, GSP-1, Moscow, V-334, Vavilova St. 28

Abstract: The first study on the effects of 1.1.3-trihydroperfluoropropanol-1, adsorbed on graphite or montmorillonite, as a tribomodifier of poly-ε-caproamide. The study on the properties of modified poly-ε-caproamide proved polyfluorinated laminate systems to be efficient tribomodifiers.

Keywords:Polycaproamide, polyfluorinated alcohol, montmorillonite, graphite

Poly-ε-caproamide (PCA) under brand Polyamide-6 is widely known as one of the main construction polymers generally applied in industry both in its filled and non-filled state [1]. The disadvantages of PCA in construction and antifriction applications, first of all its unwanted active tribo-oxidation, were also depicted [1, 2].

Recently poly- and perfluorinated substances were shown to be promising in PCA modification as they significantly improve its hydrolytic stability, light-, thermo-, wear-resistance and other useful qualities due to the unique nature of poly- and perfluorinated groups [3]. Insertion of polyfluorinated alcohols and polyfluoroalkyl-oligo-ε-caproamides based on them contributes to the improvement of PCA tribological properties due to microdoping with the said modifiers [4, 5].

Here we report the application of 1,1,3-trihydroperfluoropropanol-1 (HCF2CF2CH2OH, PFC) compositions and Na+-montmorillonite (MMT) and graphite (Zavalsky deposit) laminate systems for PCA modifiers.

PCA solid block samples doped with the modifier were produced by compression molding of a powder composition at 210-220°C under pressure 50 MPa. PFC composites with laminate structures were prepared following the published technique [6].

The tribological characteristics of filled PCA were studied with the help of a front-friction machine I47K54 between two metal counterbodies at test conditions as follows: specific load (P) 0.5 kg/cm2 and gradual increase in velocity (V) starting with 0.5 m/s. Those samples were plugs sized Ø22×12 mm, and the counterbodies were made of 3X13 steel. The sample wear was measured by weigh, and the temperature of friction heating was measured in the metal counterbody by a thermocouple fixed at ≈ 1 mm from the friction surface.

Here we studied the impact of PFC1 on the tribological characteristics of (1) graphite-filled PCA, and (2) MMT-filled PCA. The experimental results for graphite-filled PCA are shown in Table 1. It was found that at chosen velocity and load the friction of original PCA was unstable. During the friction procedure the sample was heated to 108 0C and significantly deformed, therefore its testing was stopped. Doping of the sample with 3% of graphite favors decrease in its contact temperature by the end of each test hour though small deformation of the sample still exists.

Table 1. The impact of PFC1 on both friction and wear of PCA filled with graphite (P = 0,5 kg/cm2, V = 0,5 m/s)

|

# |

Material |

Duration of friction test, h |

Friction temperature, |

Wear of sample, g |

Friction coefficient |

Notes |

|

1 |

PCA |

1 |

108 |

- |

0.35 |

Sticking of friction unit, deformation of sample |

|

2 |

PCA + 3% graphite |

1 |

103 |

0.08 |

0.32 |

Small deformation |

|

3 |

PCA + 3% |

1 |

115 |

0.0012 |

0.34 |

Sticking of friction unit within the 2nd hour |

|

4 |

PCA + 3% |

1 |

130 |

Deformation of sample |

If graphite was doped with 0.1% PFC1 the contact temperature went up so that the friction coefficient increased dramatically during the 2nd test hour resulting in the system smearing. The drop of PFC1 percentage to 0.01% resulted both in lower friction coefficient and less sample wear during the 1st hour (Table 2). Our further tests were conducted at less hard conditions under load 0.25 kg/cm2.

Table 2. Impact of PFC1 on friction and wear of PCA filled with MMT and graphite

| # | Material | Duration of friction test, h | Friction temperature, °C |

Wear of sample, g | Friction coefficient | Test conditions |

| 1 | PCA + 3% (0.01%PFC1-graphite) | 1 | 47 | 0.0010 | 0.33 | P = 0.25 kg/cm2, V = 0.25 m/s |

| 2 | PCA + 1.5% (0.01%PFC1-MMT) + 3% graphite | 1 2 |

43 51 |

0.0003 0.0009 |

0.30 0.34 |

PВ = 0.25 kg/cm2, V = 0.5 m/s |

| 3 | PCA + 1.5% (0.01%PFC1-MMT) + 3% graphite | 1 2 |

33 43 |

0.0008 0.0001 |

0.40 0.43 |

PВ = 0.25 kg/cm2, V = 0.25 m/s |

| 4 | PCA + 1.5% (0.1%PFC1-MMT) + 3% graphite | 1 2 |

40 56 |

0.0002 0.0003 |

0.43 0.41 |

P = 0.25 kg/cm2, V = 0.5 m/s |

| 5 | PCA + 1.5% (0.1%PFC1-MMT) + 3% graphite | 1 2 |

34 48 |

0.0002 0.0001 |

0.42 0.45 |

P = 0.25 kg/cm2, V = 0.25 m/s |

It seemed purposeful to compare the friction test results for the same composition samples modified, however, not with 0.1% but with 0.01% PFC1. The friction test results with variable amount of the modifier indicated that the load was the deciding factor in the development of temperature effects under friction, while the contact temperature change was negligible (1-4 °C) when the velocity grew from 0.25 to 0.5 m/s.

The results bear witness to the notable positive role of PFC1 in the friction process of the composition polymer materials. Thus the rise of PFC1 content from 0.01% to 0.1% in PCA/MMT-PFC1/graphite composition decreases those composition wear by 2-3 times (samples #2 and #4). The introduction of the complex filler (MMT-PFC1/graphite) improves the tribological behaviour of those compositions as to compare with modified graphite (table 2).

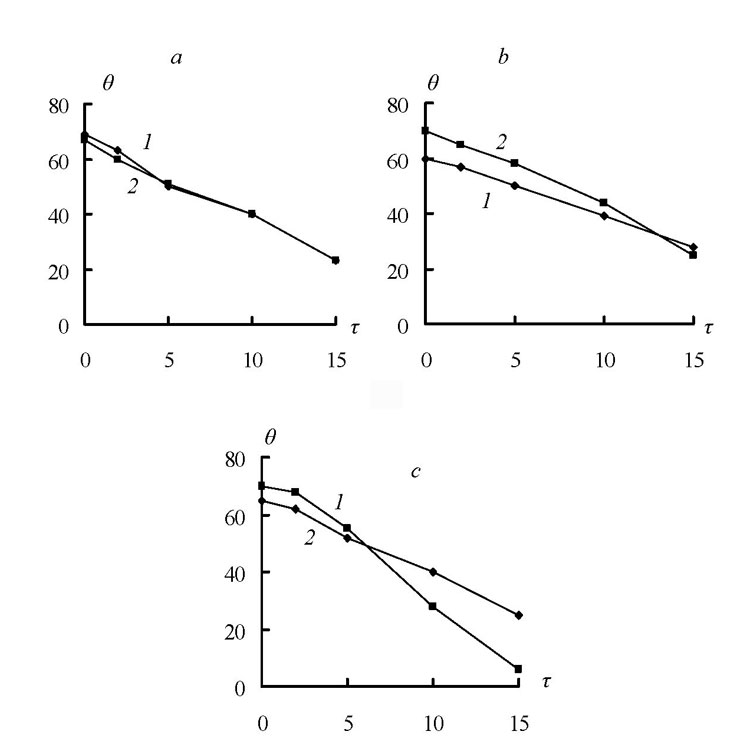

Gaining the understanding of the physico-chemical behaviour of the surface state of the studied polymer samples under wear we determined their contact angles of wetting (CAW) prior and after the experiments. The measurement of CAW was conducted on the sample surface (muft abutments Ø22×12mm) with the help of MIN-2M microscope. The results are shown in Figure 1.

Fig. 1. Contact angles of wetting for PCA samples.

θ - contact angles of wetting

(degree), τ - period (min).

a - original PCA: 1 - prior to friction, 2 - after friction;

b - PCA + 0.1%PFC1-graphite:1 - prior to friction, 2 - after friction;

c- PCA + 1.5% (0.01% PFC1-MMT)

+ 3% graphite: 1 - prior to friction, 2 - after friction.

From Fig. 1a one may see that the sample surface looked as if unchanged after friction procedures. It was due to the friction specific properties that resulted in very significant deformation of the sample and practical refreshment of all the surface. That is why in this case it would be incorrect to use those results in the description of friction test results.

The increase in the original CAW value for the friction tests from 60° to 70° may be due to the introduction of less polar graphite and the impact of PFC1 with its surface (CF2-CF2)-groups (Fig. 1b). By the end of the experiment the sample CAW value decreases after friction that is usually bears witness either to the formation of micropores, or to the fact that the drop reached some surface zones that had undergone deeper oxidation due to friction.

The introduction of polyfluorinated MMT contributes to more intensive decrease in CAW value to about ~5° after 5 minutes residence of a water drop on the surface. Such rather unusual alteration indicates may be that modified MMT, both due to its original hydrophilicity and microquantity of "acid" PFC1, when blended with graphite, favors the formation of microporous surface with, possibly, more active polar zones.

Therefore, laminated systems modified with microquantity of PFC are efficient tribomodifiers that contribute to the stabilization of the friction process of PCA filled with those systems.

List of references

1. Novakov I.A., Storozhakova N.A., Krasnov A.P., Ivanov V.B., and Priymak V.V. Modification polycaproamide

1.1.5-trihydroperffluoropentanol and properties of the fibers H.M. conn. A and B. 2005, V. 47, Issue

12, P. 2186-2190.

2. Novakov I.A., Storozhakova N.A., Zubavichus Y.V., Krasnov A.P., and Priymak

V.V. Effect 1.1.5-trihydroperffluoropentanol on the structure of unoriented poly-ε-caproamide films,

H.M. Conn. A and B. 2007, V. 49, Issue. 3, P. 559-565.

3. Storozhakova N.A. Regularities of modification

of poly-ε-caproamide polyfluorinated compounds, especially the properties and applications. Diss.

Doctor Of Chem. Science. Volgograd: VSTU, 2007, P. 43.

4. Krasnov A.P., Storozhakova N.A., Bazhenova

V.B., Afonicheva O.V., Naumkin A.V., Zubavichus Y.V., Rashkovan I.A., Kazakov M.E., and Novakov I.A.

Effect of chemical structure of polyfluorinated alcohols on the tribological properties of poly-ε-caproamide

/ Friction and wear. 2008, V. 29, p. 51-57.

5. Novakov I.A., Krasnov A.P., Rakhimova N.A., Bazhenova

V.B., Afonicheva O.V., Mit V.A., Naumkin A.V., and Kosenkova S.A. Effect of esters of oligomers polyfluoroalkil

ε-aminocaproic acid on tribochemical properties of poly-ε-caproamide // Proceedings of the Volgograd

State Technical University: Intercollege. Sat Scient. Art. / VSTU, Volgograd. 2010, V. 1 (39), p.

125-129.

6. Rakhimova N.A., Kudashev S.V. Hydrophobicity bentonite polyfluorinated alcohols

// Proceedings of the Volgograd State Technical University: Intercollege. Sat Scient. Art. / VSTU,

Volgograd. 2010, V. 2 (62), P. 49-53.

Recommended for publication by Prof. Alexander I. Rakhimov

Fluorine Notes, 2011, 74, 3-4